Medical Products

Quality that's Second to none

At Basilius, we know what it takes to manufacture high-quality products for the medical industry. We supply a variety of customers with dental and medical (non-invasive) devices. Adherence to customer quality standards and documentation requirements are always key to meeting and exceeding expectations. Which is exactly what we plan to do.

Injection Molding

past medical Manufacturing projects

Medical products often require small tolerances and a higher quality standard. We’ve already helped bring a variety of products to life.

- Overmolded screw plunger

- UV Phototherapy Comb

- Vessel preparation components

why choose basilius

For your medical Product manufacturing

UV Additives for Injection Molded Parts

Plastics can degrade and lose critical material properties over time, but this can be prevented by proper material selection.

Material Drying 101

Drying materials before molding is important for part integrity and cosmetics. Learn the basic of how material is dried why it’s important.

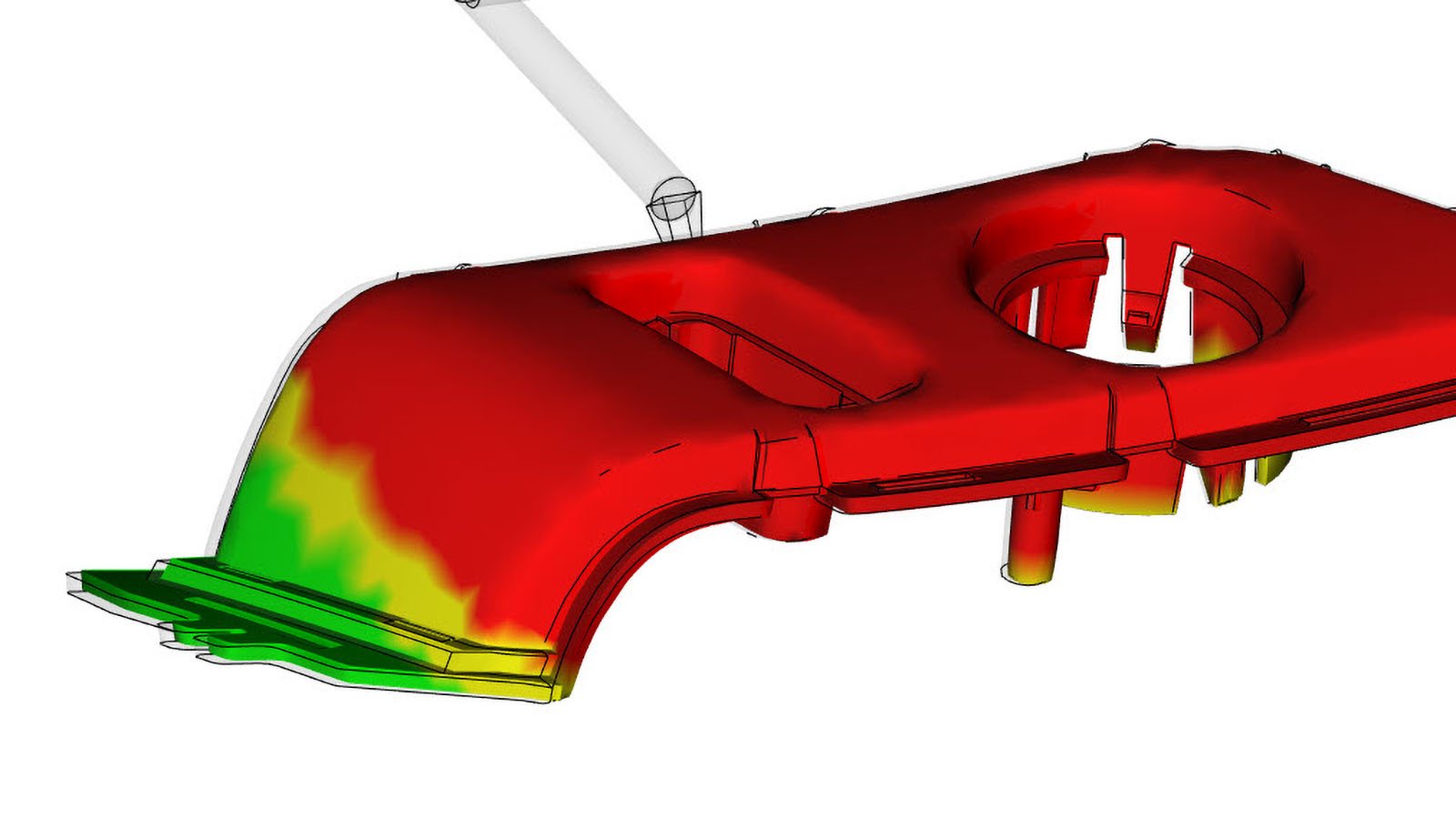

Designing for Molding: Warp

Plastic parts can warp as they cool. We can predict and compensate for this using software and design best practices.