Overmolding Processes

Overmolding uses the same injection molding process but differs in that material is molded around a substrate.

Overmolding uses the same injection molding process but differs in that material is molded around a substrate.

When selecting material, both the substrate and the overmold material should be considered. This guides will help you select the right materials.

Designing your part correctly for the overmolding process is critical. That design process starts with understanding the function of the part.

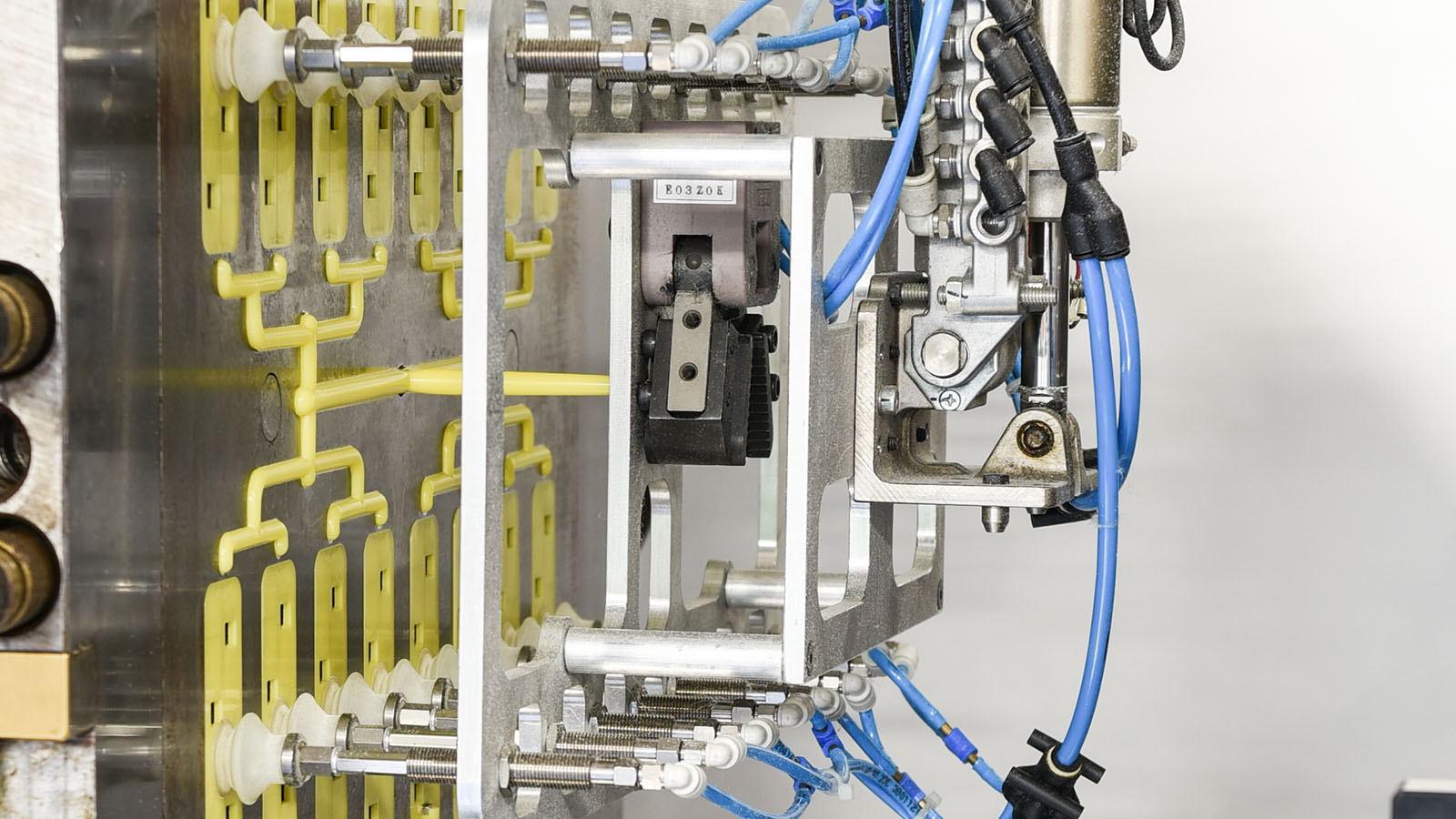

Hydraulic actuators are used for various injection molding applications such as: slides, core pulls, ejection systems, and unscrewing cores.

It can be challenging to compare quotes accurately to assess your best option. The article describes why quotes vary from supplier to supplier.

Ultrasonically welding plastics creates a permanent, water-resistant, and impact resistant connection between two plastics that avoids the use hardware.

Pad printing is a process for applying ink-based graphics to various surfaces and is commonly used the injection molding industry.

How injection molded parts are handled after molding has design implications for the mold build. This guide will help you understand those implications.

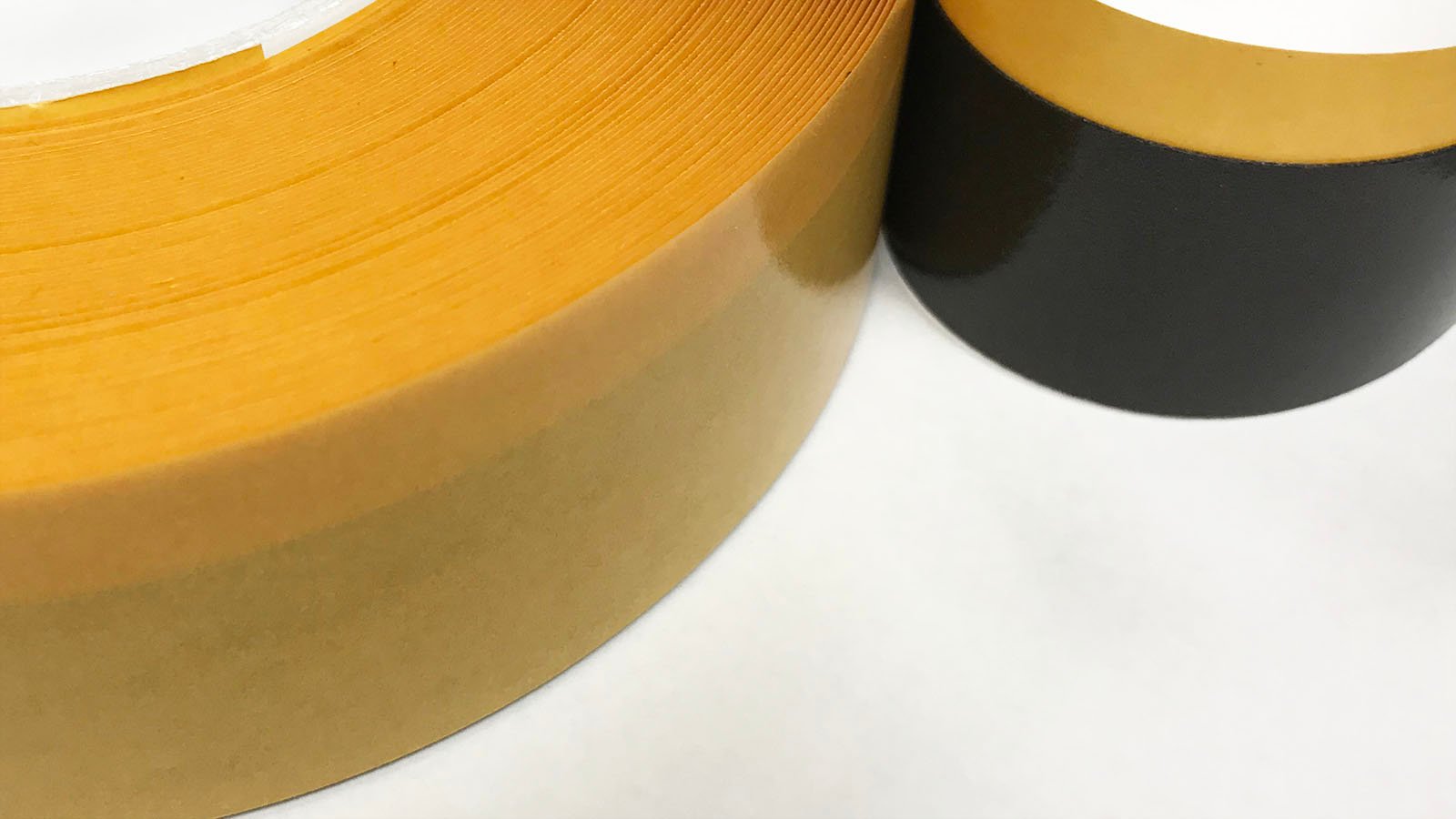

Foam tape is great alternative to mechanical connections or chemical bonding between injection molded components and various substrate materials.

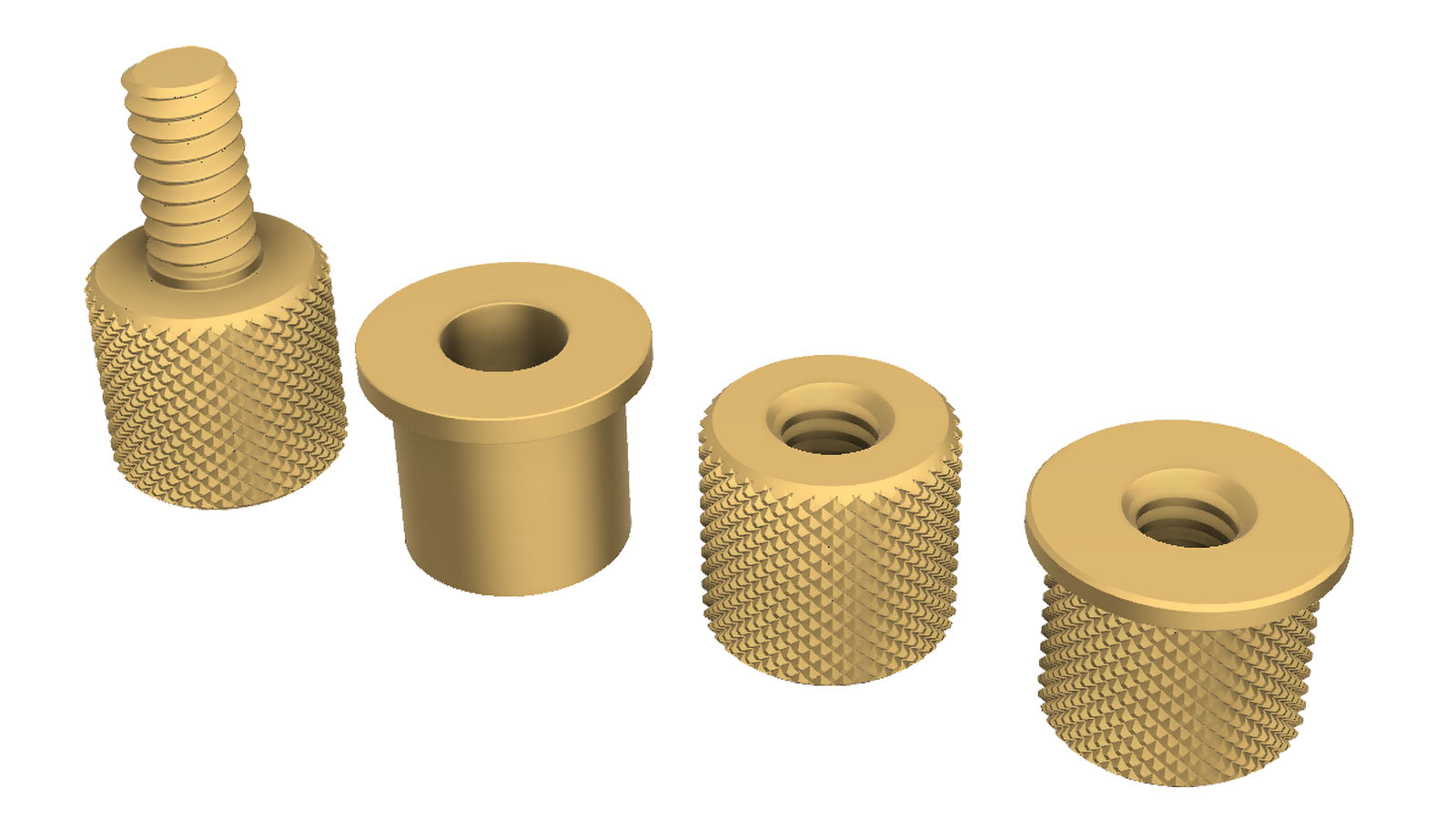

From female threaded in custom designs, there are several design options for molded-in inserts.

© 2025 Basilius. All Rights Reserved.