Switching Your Injection Molding Supplier

Switching molders is not an easy task. Use this evaluation process for finding a reliable, trustworthy injection molding supplier.

Switching molders is not an easy task. Use this evaluation process for finding a reliable, trustworthy injection molding supplier.

For some molding applications, it may be best to CNC machine holes and threads after injection molding instead of investing upfront in tooling.

Plastics can degrade and lose critical material properties over time, but this can be prevented by proper material selection.

For many injection molding applications, some assembly may be required. See how your injection molder can provide assembly services.

Hot stamping is a process used for generating graphics or lettering on plastic parts.

Changing from metal to plastic can yield many advantages, such as: cost savings, weight savings, and simplified/quicker manufacturing.

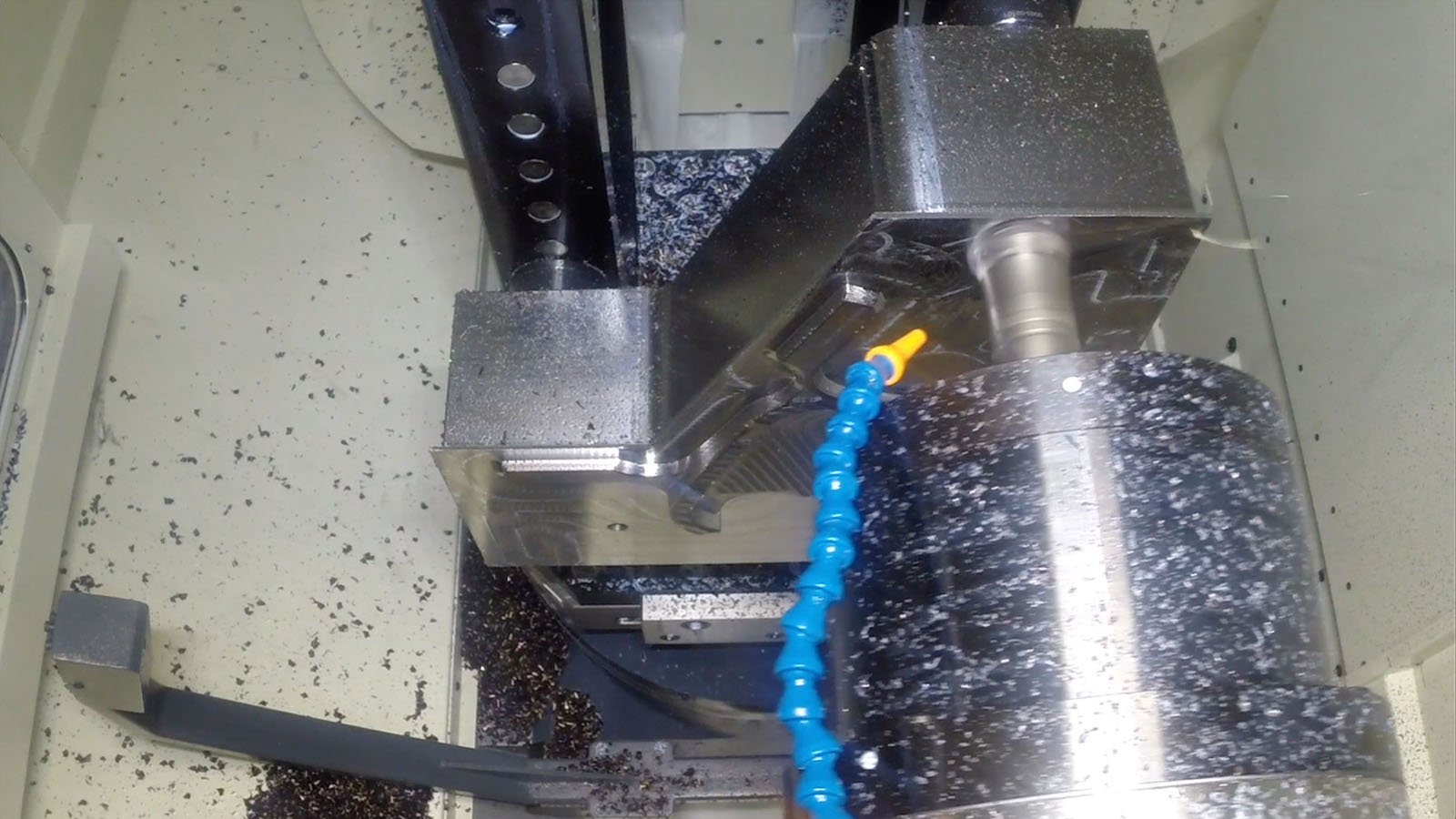

Couple ever advancing plastics with more complicated part designs and the need for your injection molder to invest in technology becomes apparent.

There are thousands of mold builders around the world. In trying to source your molding you could end up wondering if it even matters who you use.

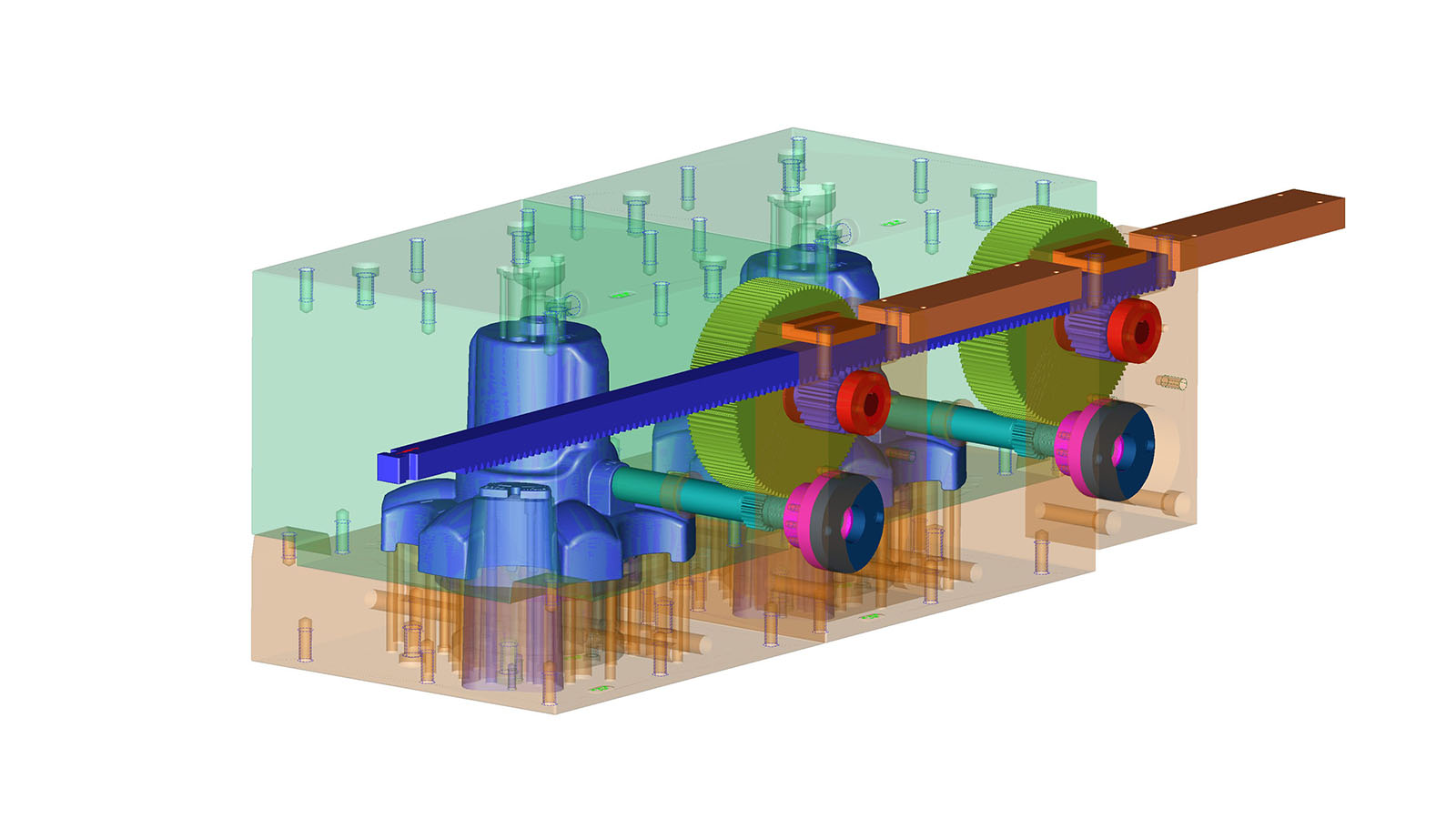

We worked with a leading pump manufacturer to provide them a two cavity mold with both hydraulically controlled unscrewing cores and hand loads.

Basilius Inc. has a history going back to the early 1950s. This is a story of how we got started and how we ended up where we are today.

© 2025 Basilius. All Rights Reserved.