Adding Inserts to Injection Molded Parts

In this article, we will cover the various ways that inserts can be added to an injection molded part.

In this article, we will cover the various ways that inserts can be added to an injection molded part.

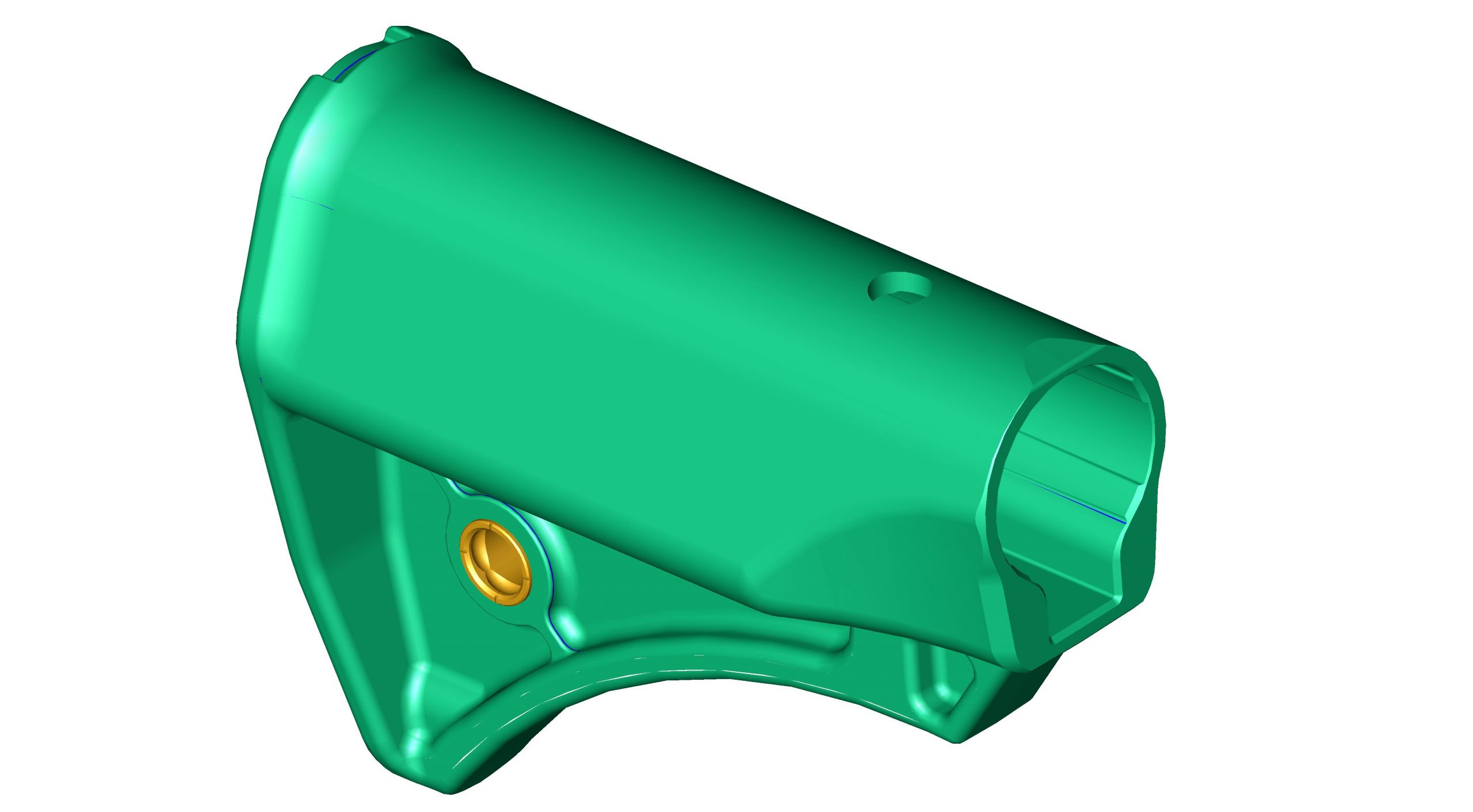

Overmolding plastic may include anything from ergonomic grip features to to metal threaded inserts. Here is a breakdown of how the these processes work.

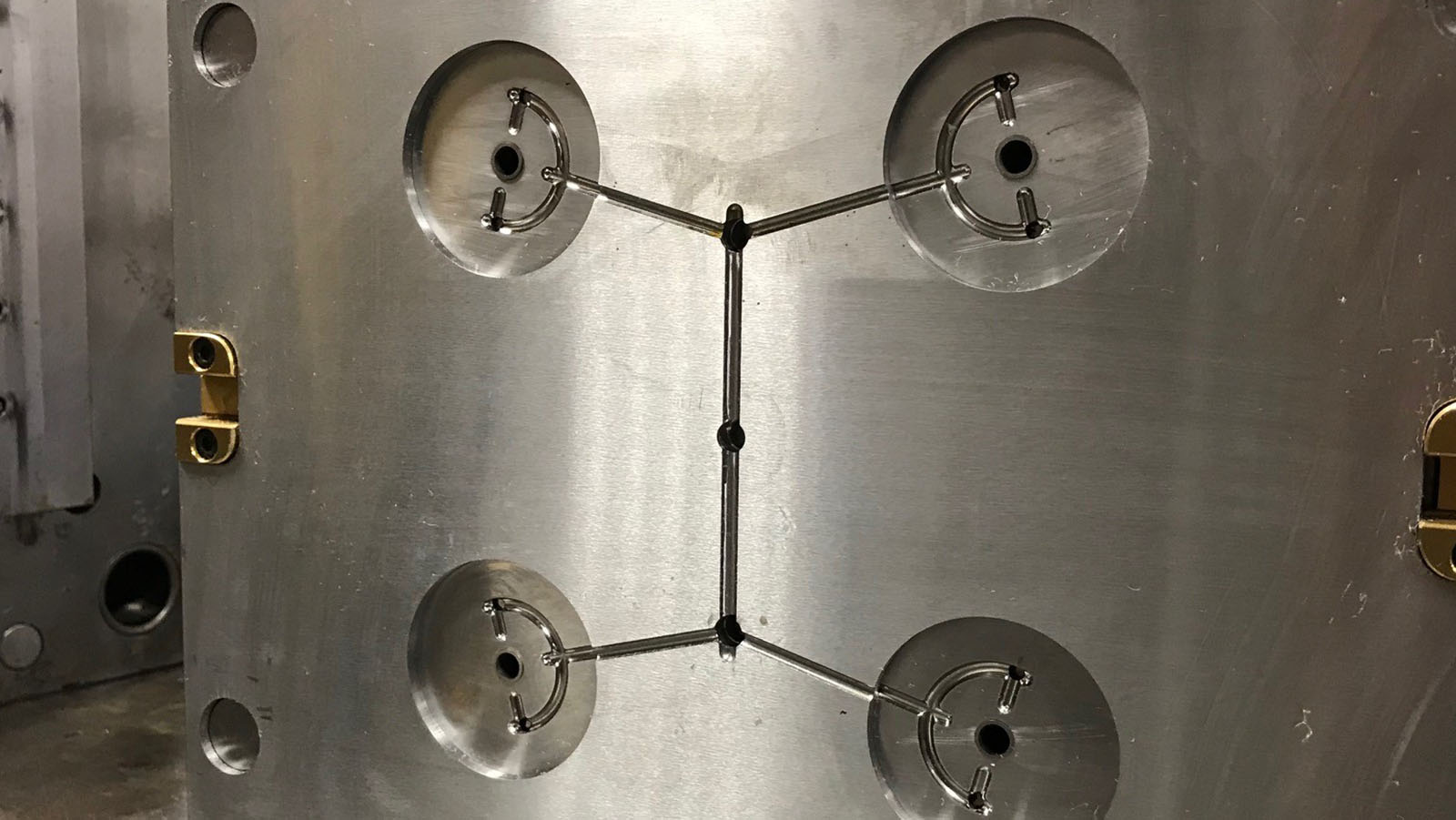

In this high volume injection molding application, we are running an automatic insert loading operation.

The cost of injection molds vary based on the part and the application. This post will help you understand the contributing factors to the cost of a mold.

There’s no doubt 3D printing has become all the craze for everyone from hobbyist to fortune 500 companies. And why wouldn’t it be?

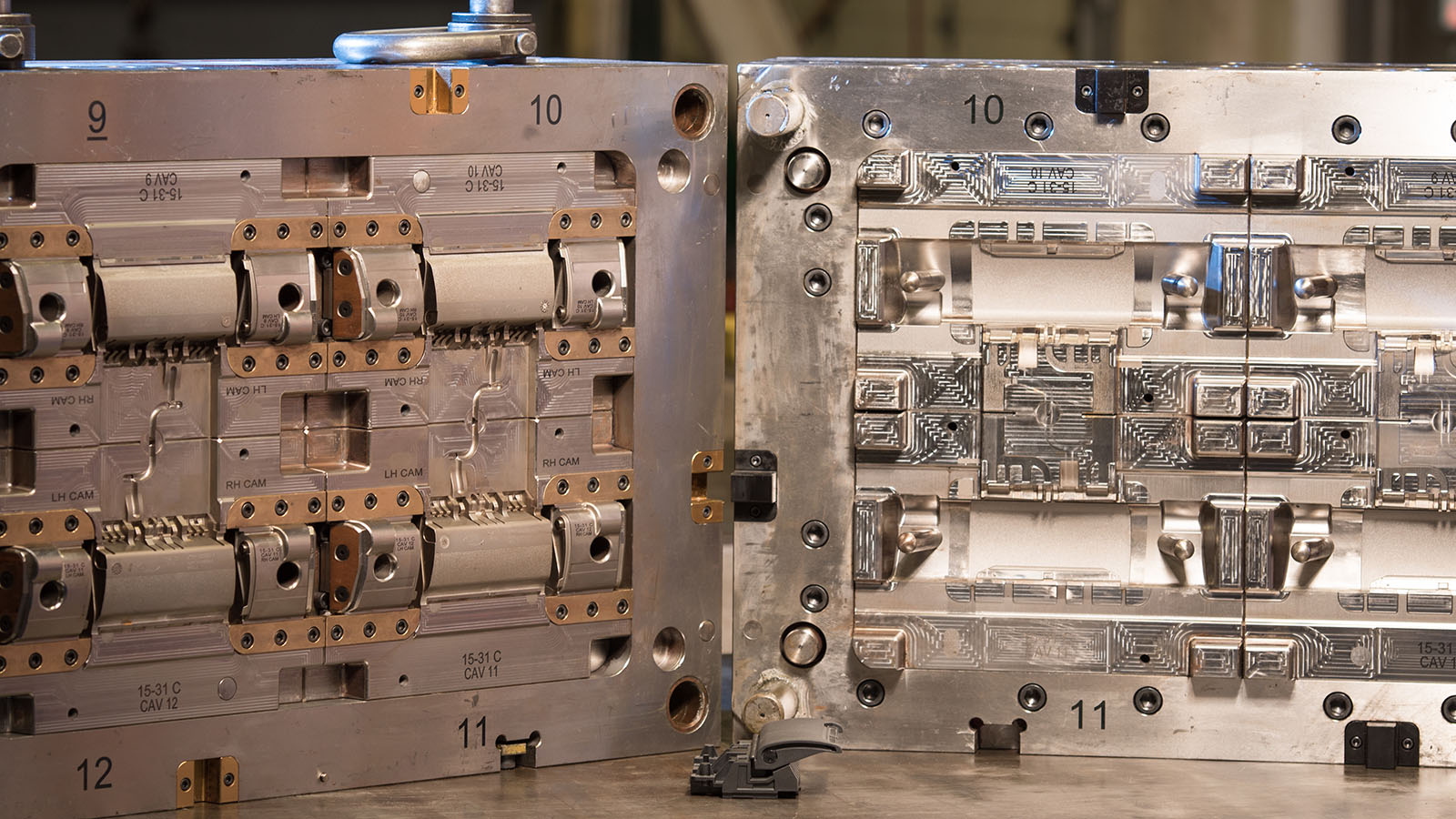

The part looks simple but required several cam actions and an over-molded insert.

When a mold is ran for the first time there’s a lot to consider. From testing mold functionality to checking dimensions, this is what to expect.

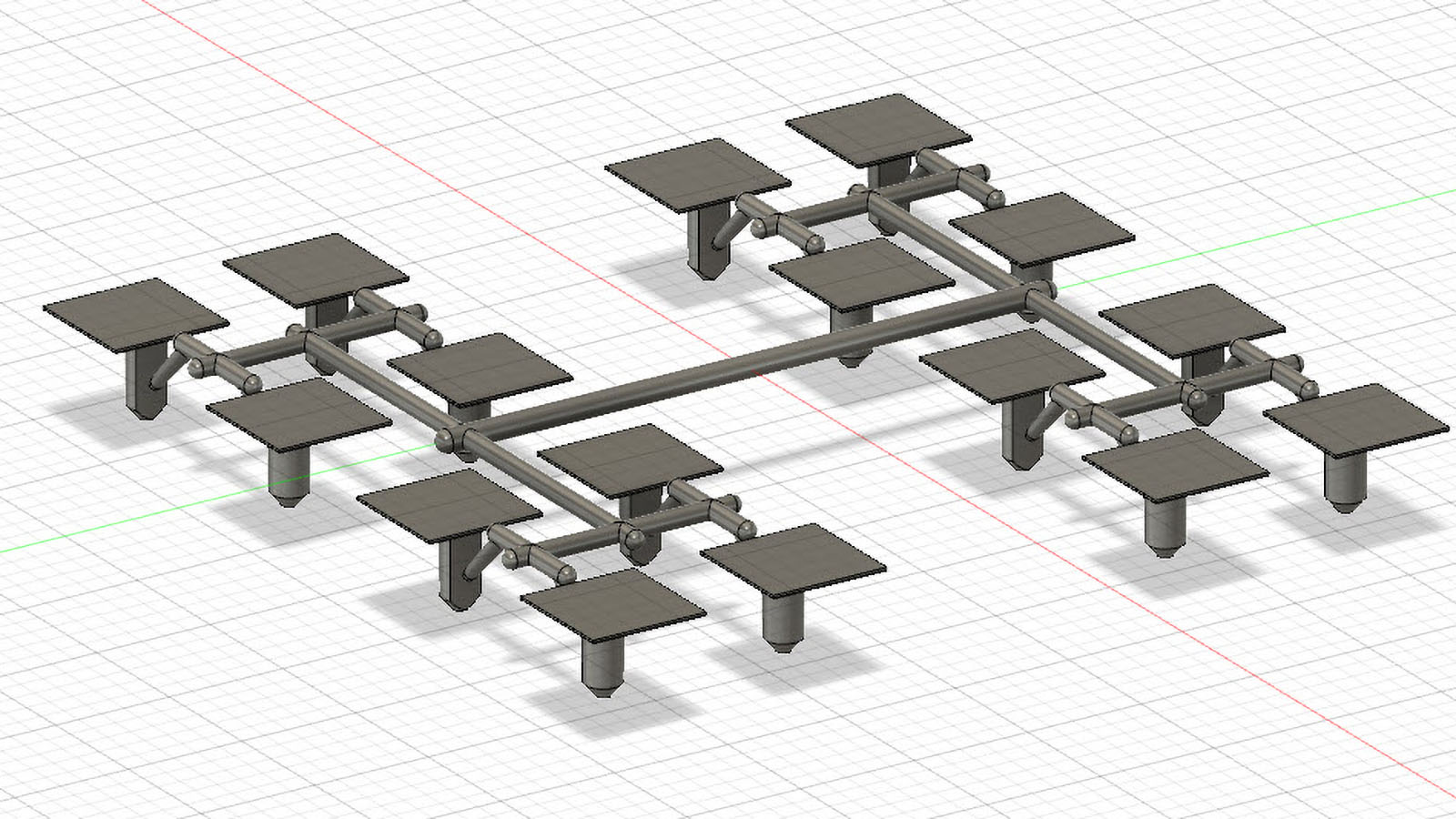

Cycle time and producing an extremely high volume of parts consistently and reliably is of the utmost importance for cap and closure manufacturers

Cavitation can have huge implications on both piece price and mold cost. See how we can do a cost benefit analysis to find the right fit.

The cost of machine time in the injection molding industry is not standardized. See what goes into the different rates across the industry.

© 2025 Basilius. All Rights Reserved.