Designing for Molding: Warp

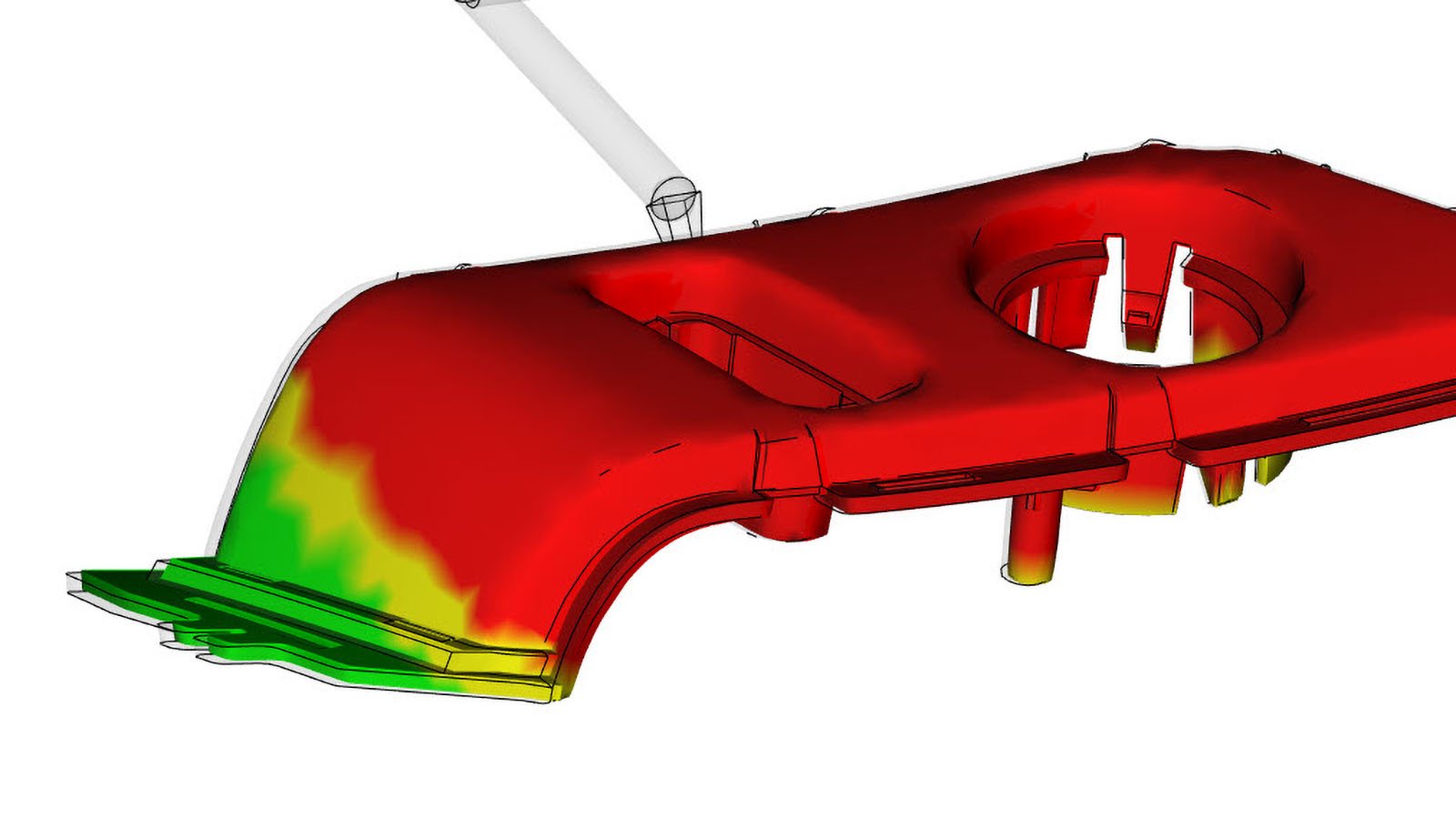

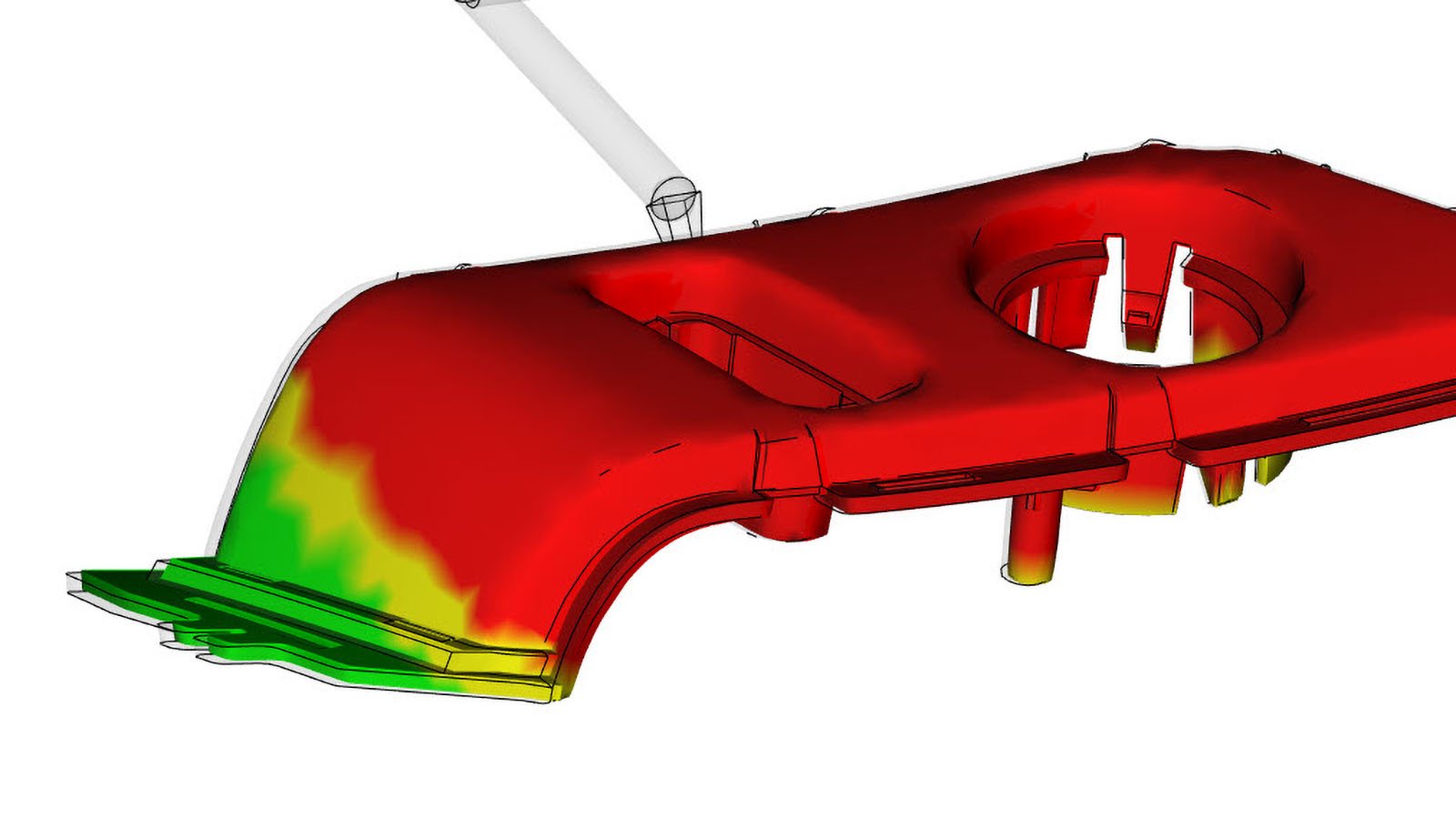

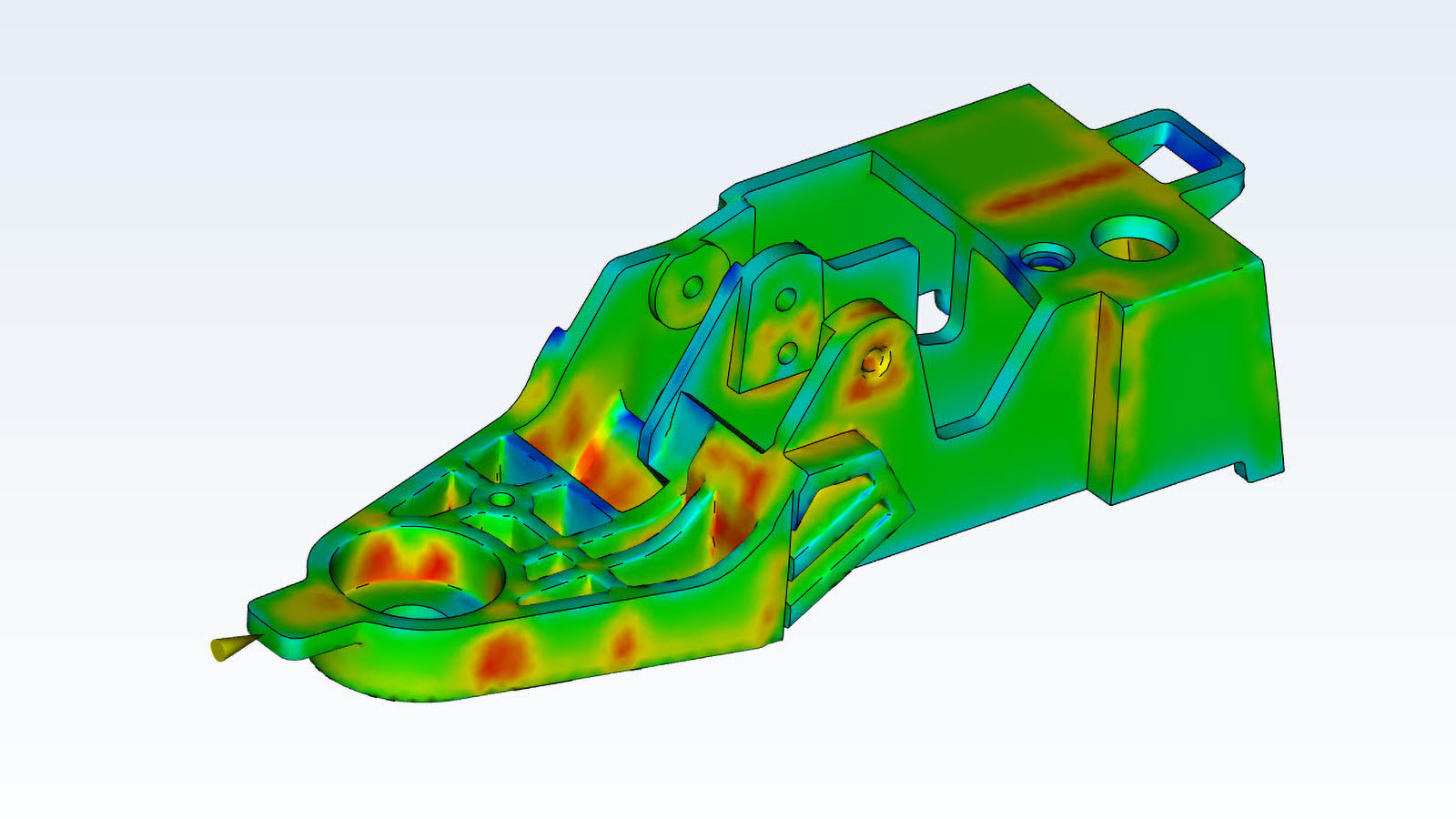

Plastic parts can warp as they cool. We can predict and compensate for this using software and design best practices.

Plastic parts can warp as they cool. We can predict and compensate for this using software and design best practices.

Drying materials before molding is important for part integrity and cosmetics. Learn the basic of how material is dried why it’s important.

Having uniform wall thickness is important for the injection molding process. Here we will discuss why that is and how to design for molding.

If you’ve been inside a mold shop you’ve likely seen a few electrical discharge machines (EDM). Here’s how they work and how he technology is utilized.

Proper preventative maintenance is critical to life of injection mold tooling. Here we go over the basics of making your tools last.

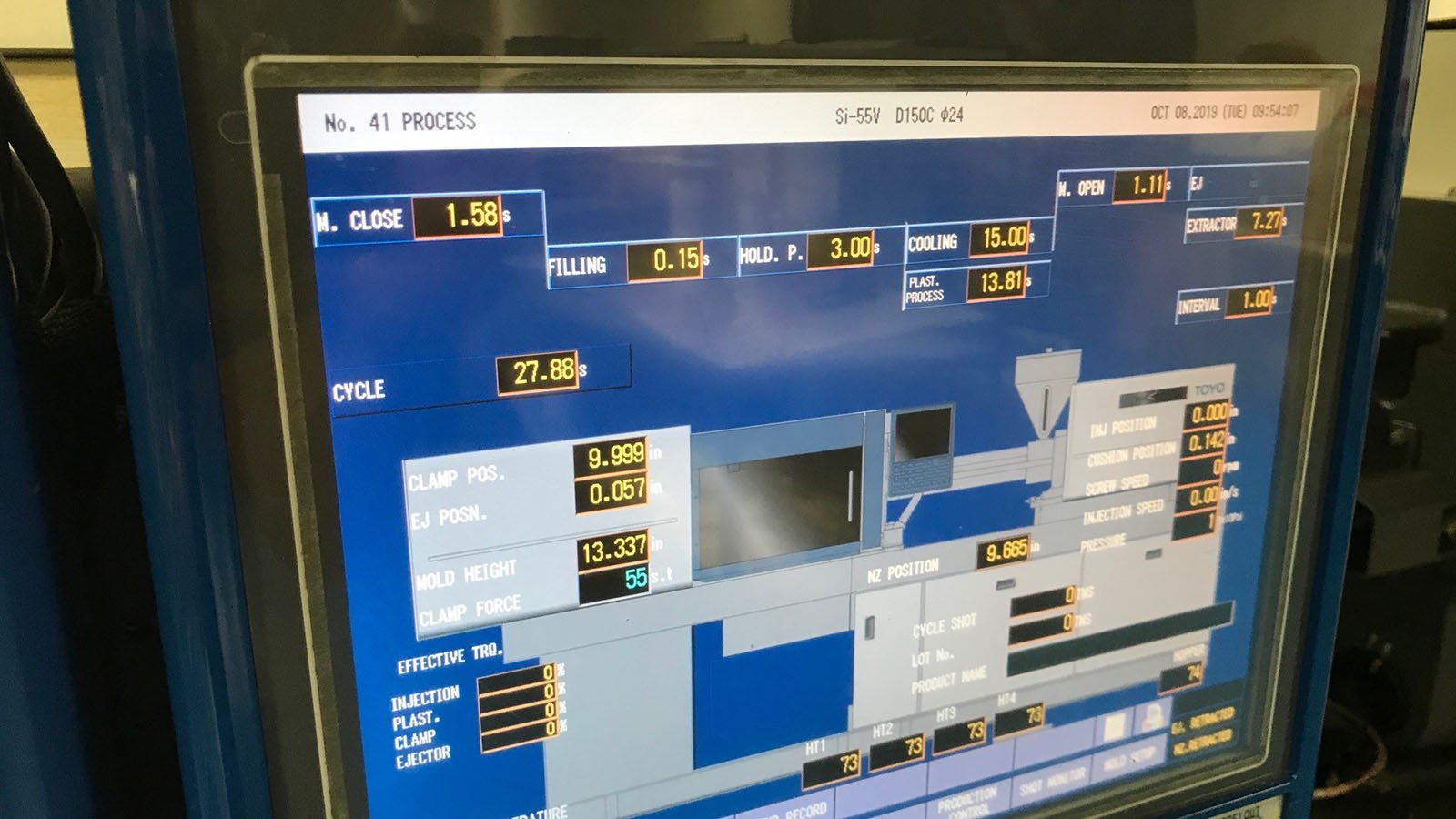

Here we look at the injection molding process and the different methodologies for controlling it.

There are a handful of different materials used for building injection molds. It’s important to understand the application of each.

Being in the industry we use the lingo as if everyone already knows what we’re talking about. We hope to clarify some of the terminology here.

The strength of being a mold builder and injection molder is realized through the entire process. From initial design to long term production.

Automation is critical for injection molders to maintain the highest quality and delivery standards.

© 2026 Basilius. All Rights Reserved.