Designing Injection Molds for Robotics

How injection molded parts are handled after molding has design implications for the mold build. This guide will help you understand those implications.

How injection molded parts are handled after molding has design implications for the mold build. This guide will help you understand those implications.

Basilius Inc. has a history going back to the early 1950s. This is a story of how we got started and how we ended up where we are today.

Overmolding plastic may include anything from ergonomic grip features to to metal threaded inserts. Here is a breakdown of how the these processes work.

Check out how Basilius deployed a proprietary mold base design to decrease lead times and reduce costs without sacrificing quality.

Class 101 molds are built for high volume production environments. See what it takes to classify a mold to the 101 standards.

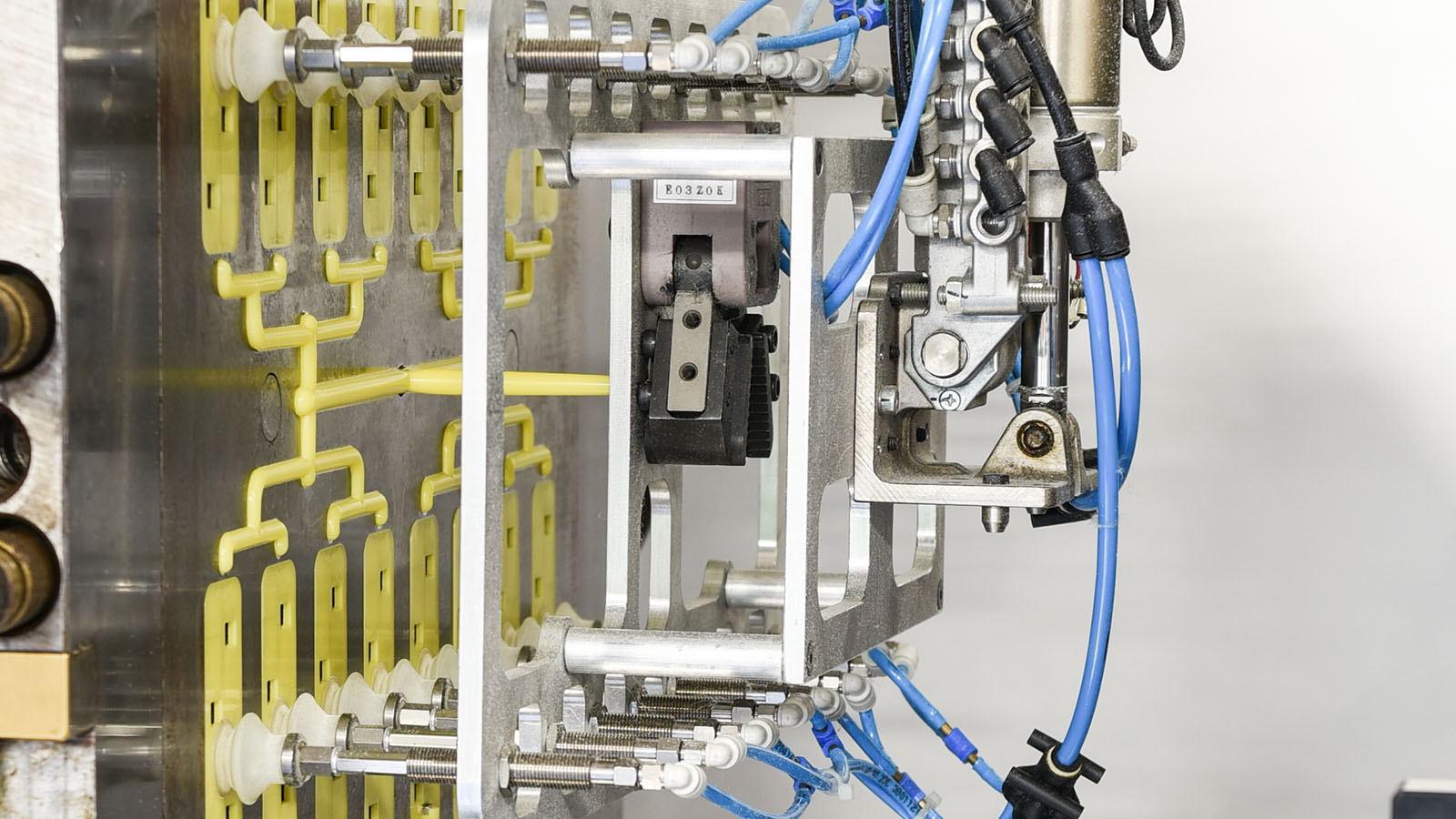

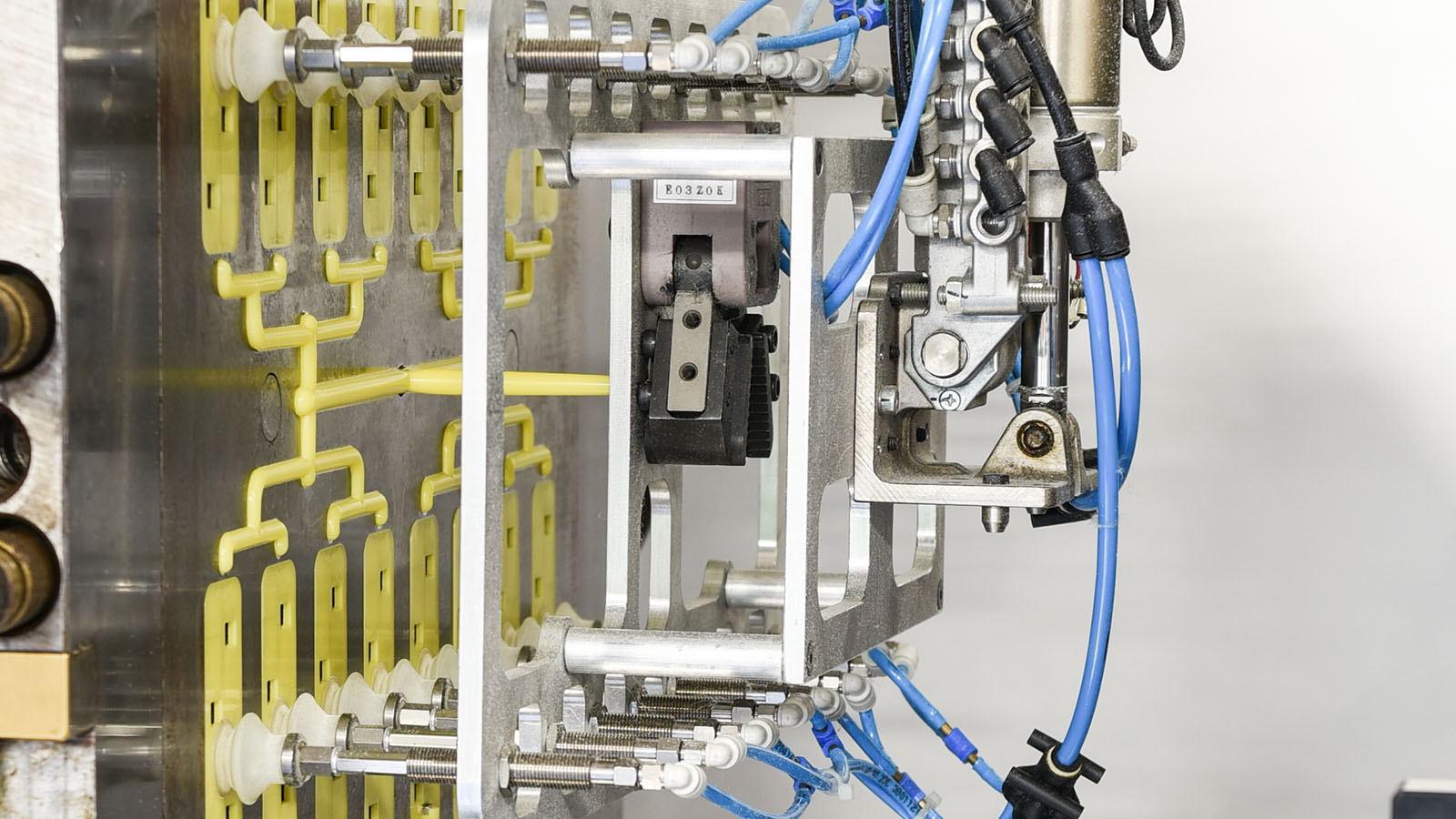

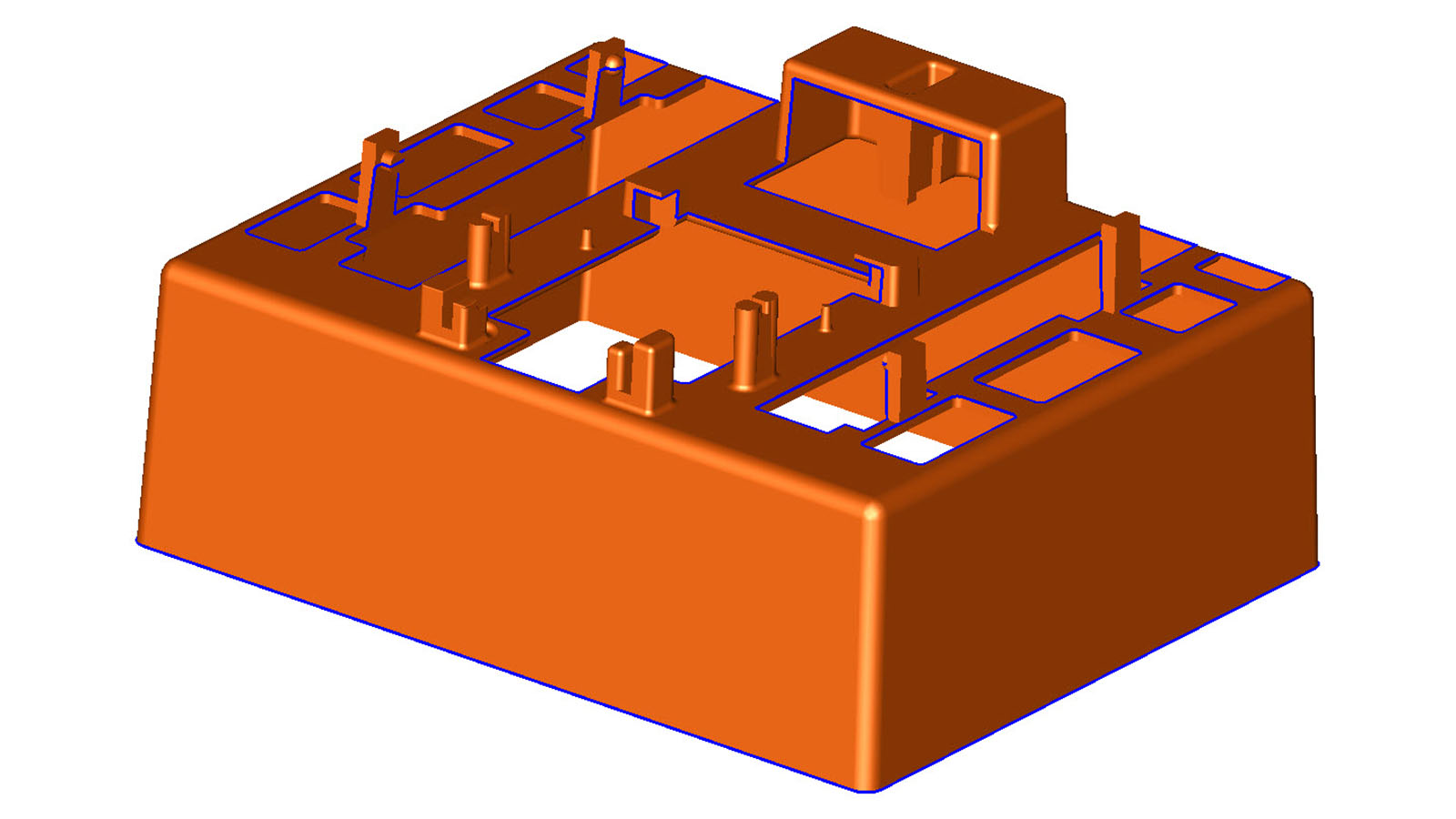

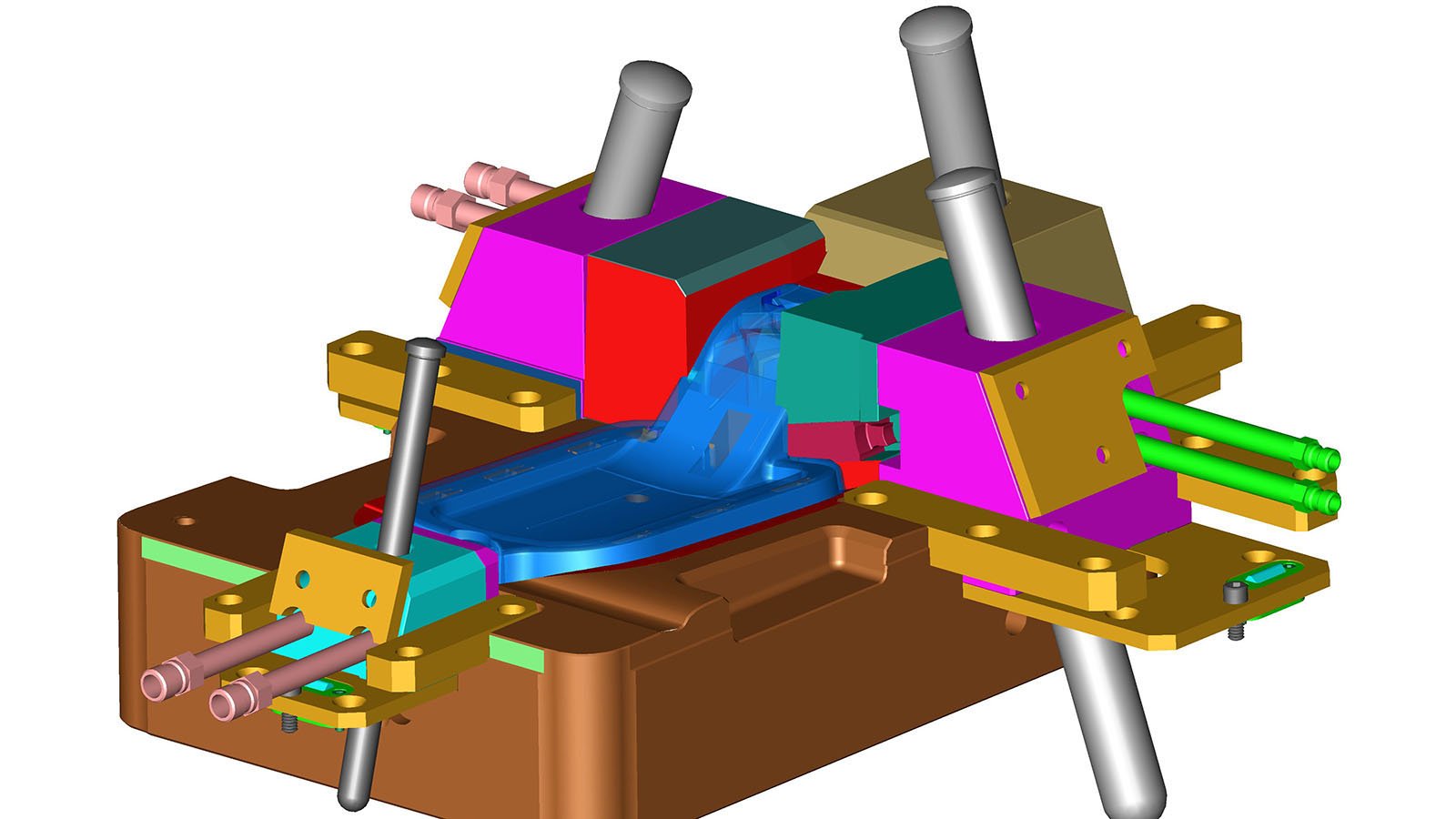

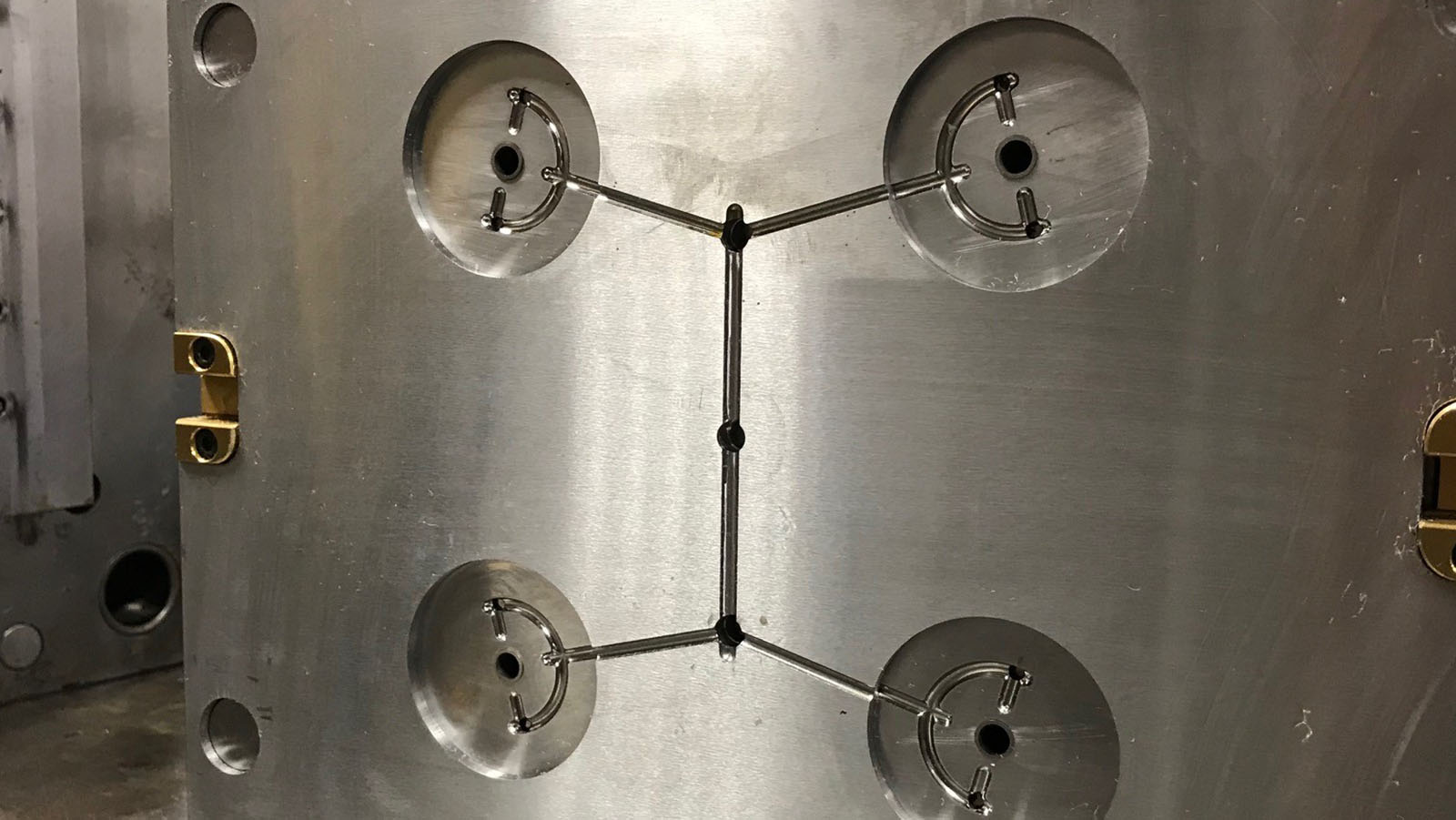

The part looks simple but required several cam actions and an over-molded insert.

Hinges and clips are common features of injection molded parts. See how they are designed for injection molding.

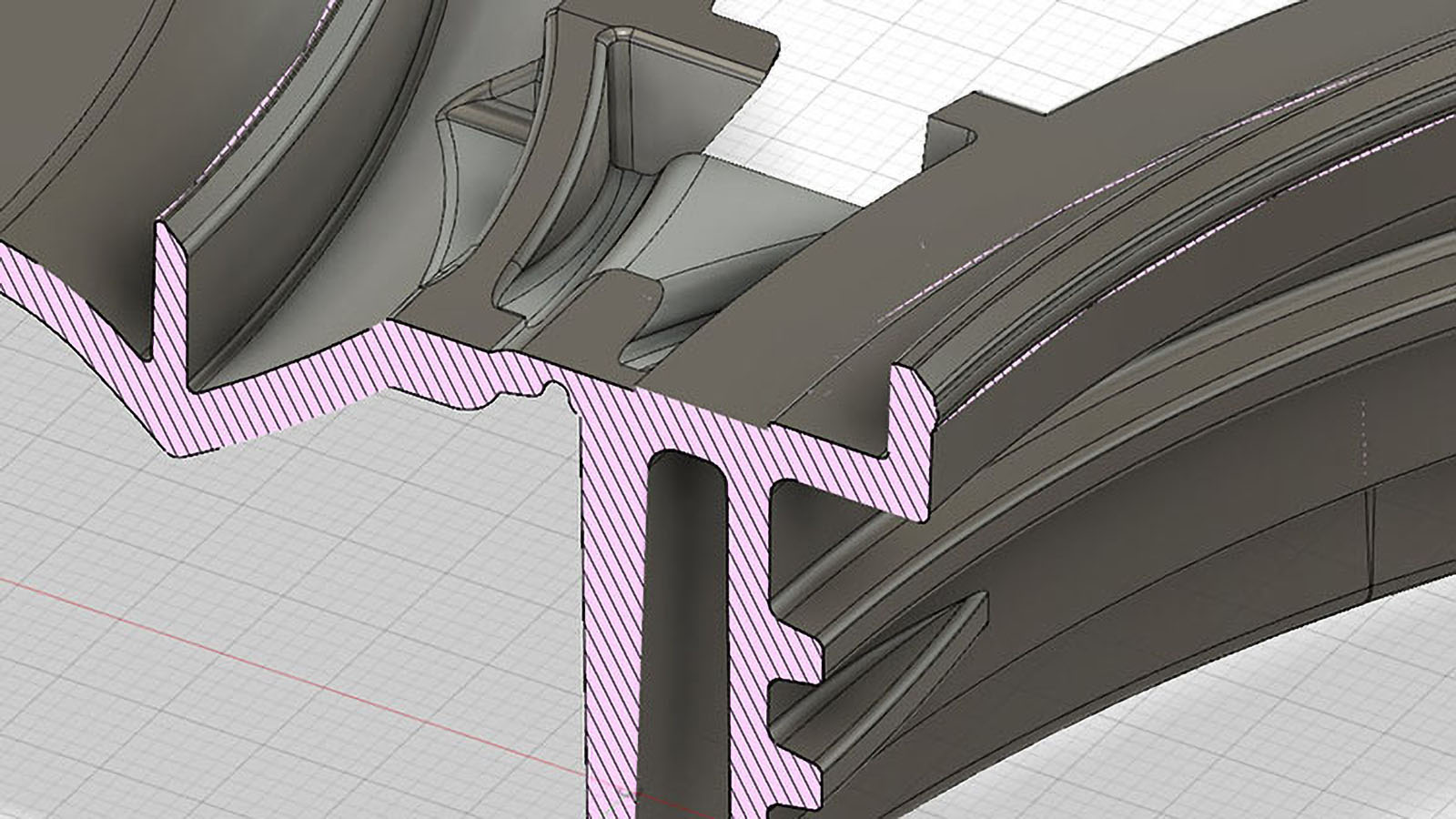

Every injection molded part has a parting lines. See how we decide where to put them and how they are designed.

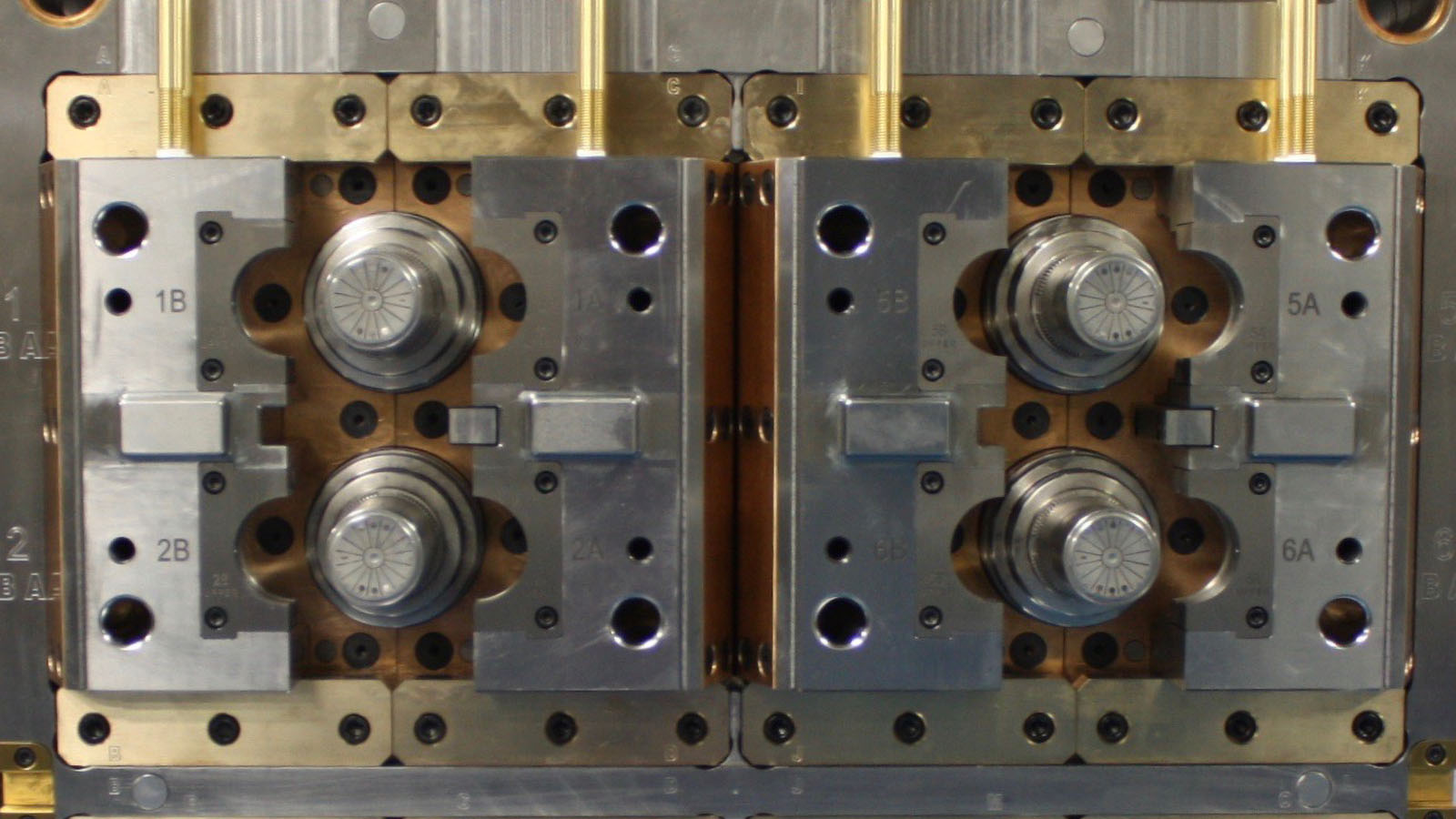

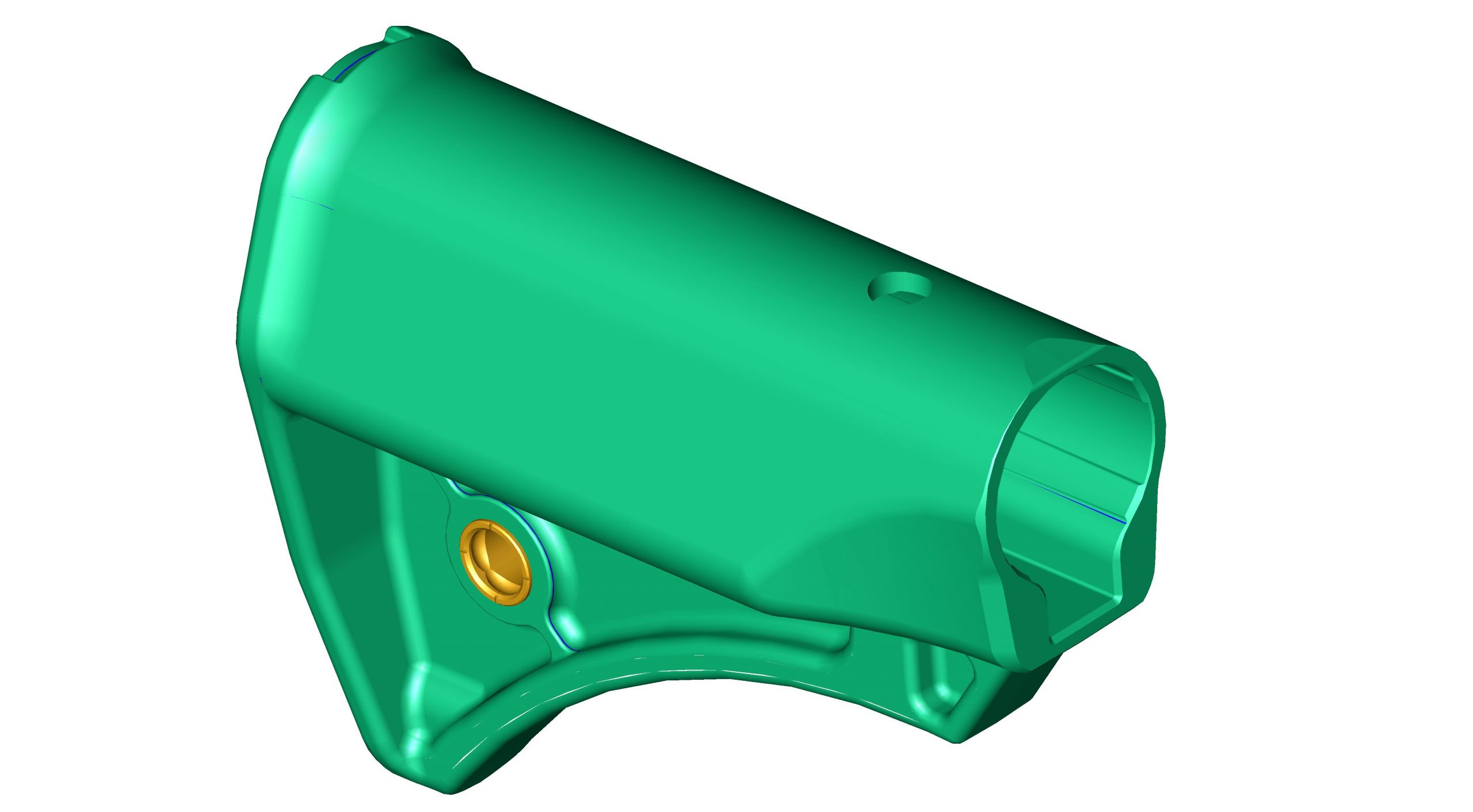

This mold was built for a large tier one automotive supplier. The part has several undercuts and features making the mold design more advanced than usual.

When a mold is ran for the first time there’s a lot to consider. From testing mold functionality to checking dimensions, this is what to expect.

© 2025 Basilius. All Rights Reserved.