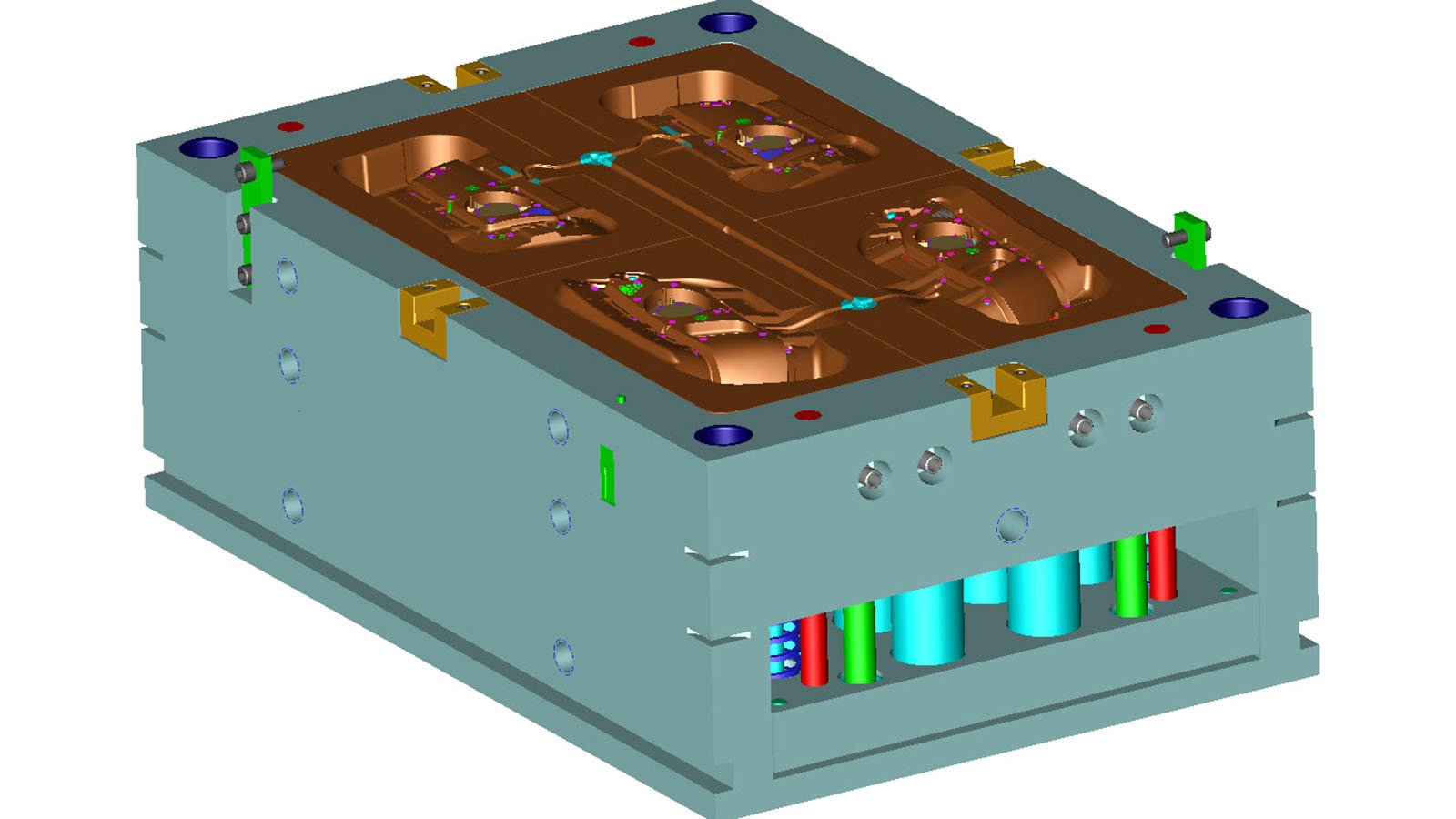

32 Cavity Cap Mold

Cycle time and producing an extremely high volume of parts consistently and reliably is of the utmost importance for cap and closure manufacturers

Cycle time and producing an extremely high volume of parts consistently and reliably is of the utmost importance for cap and closure manufacturers

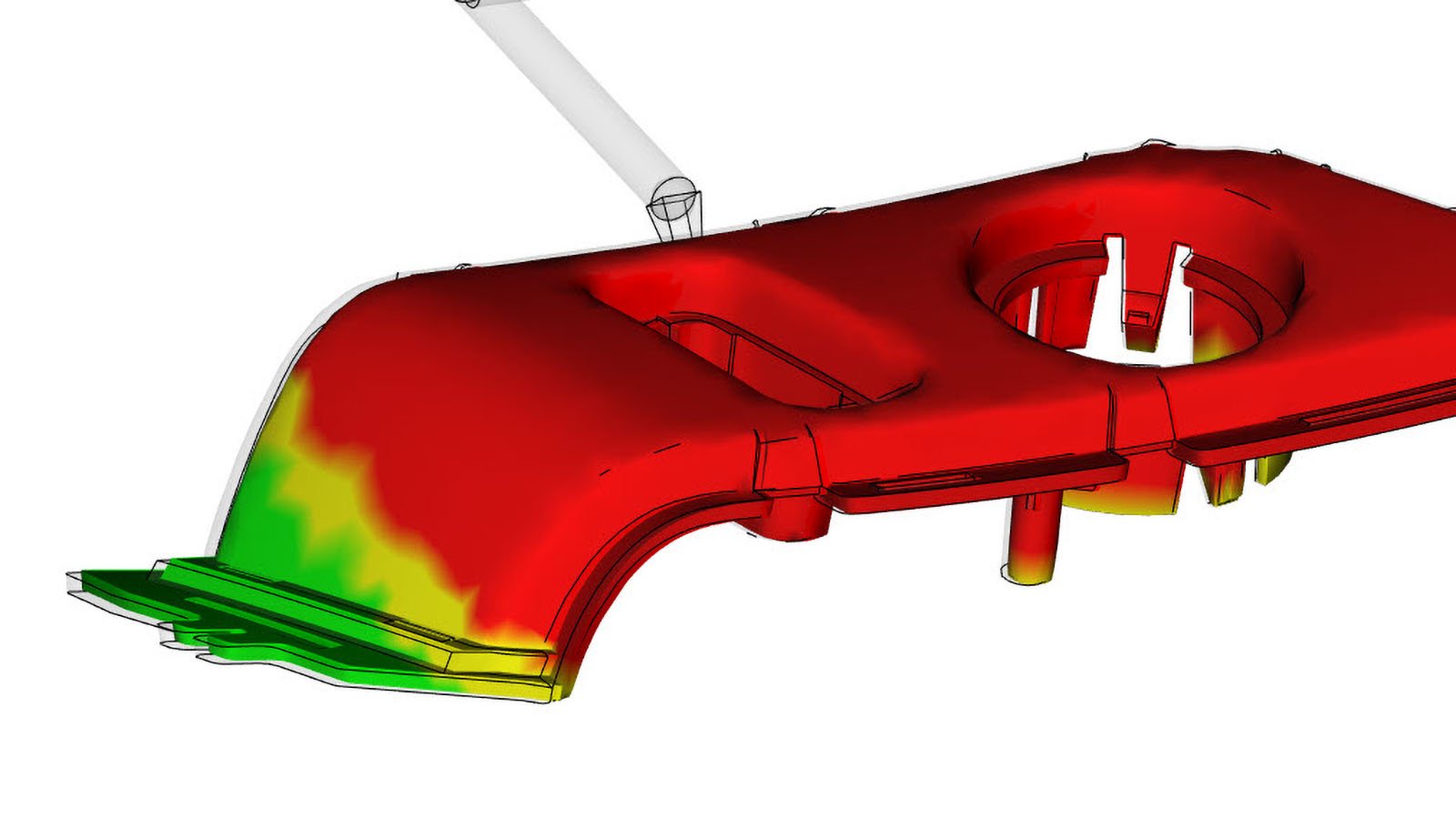

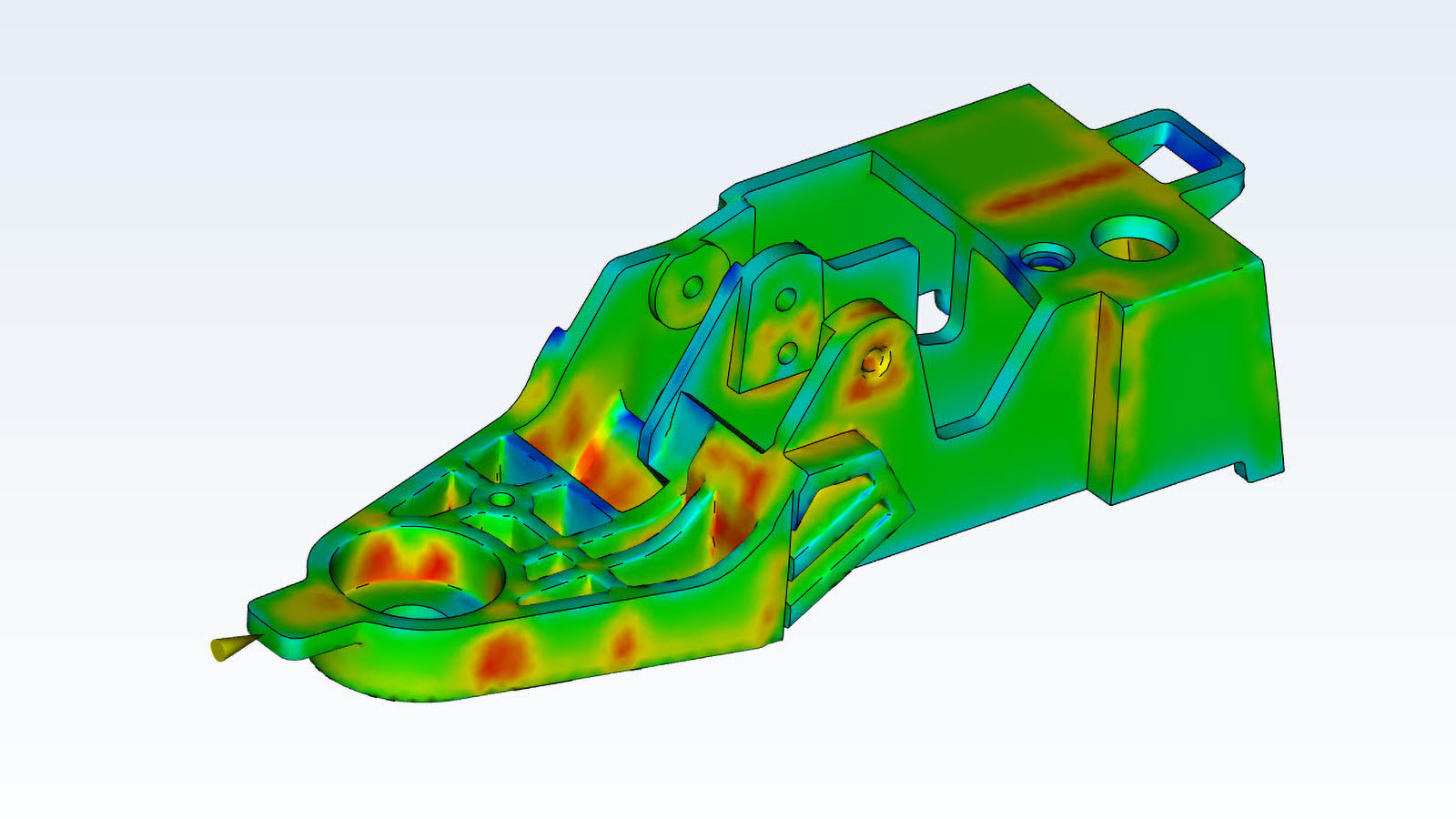

Plastic parts can warp as they cool. We can predict and compensate for this using software and design best practices.

There are thousands of plastics available to injection molders. Learn about the broad categories of materials.

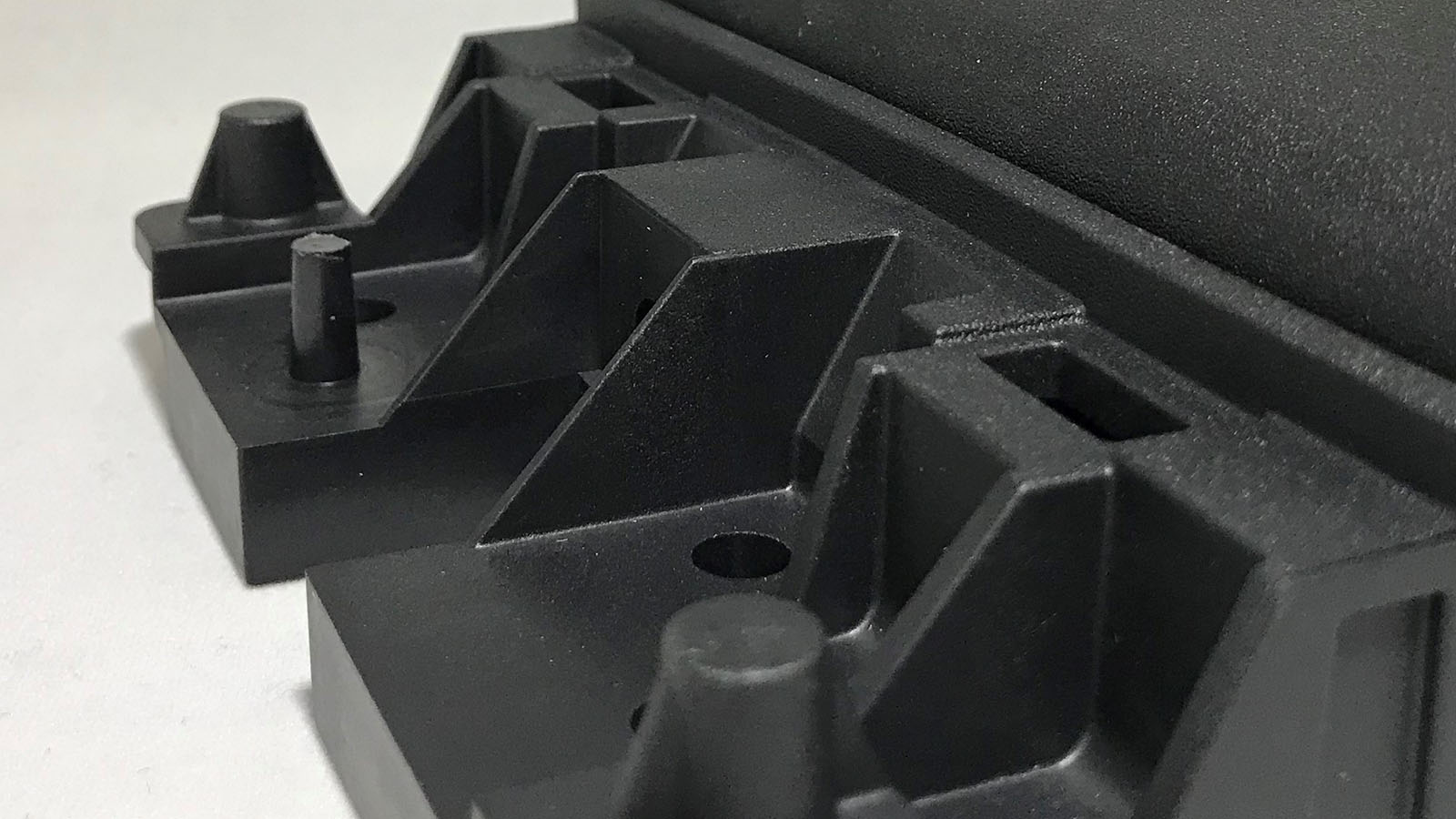

Drafting is an important design feature for mold functionality and part quality.

There are many different types of surfaces finishes available for plastic parts. Some of which may require minor design changes.

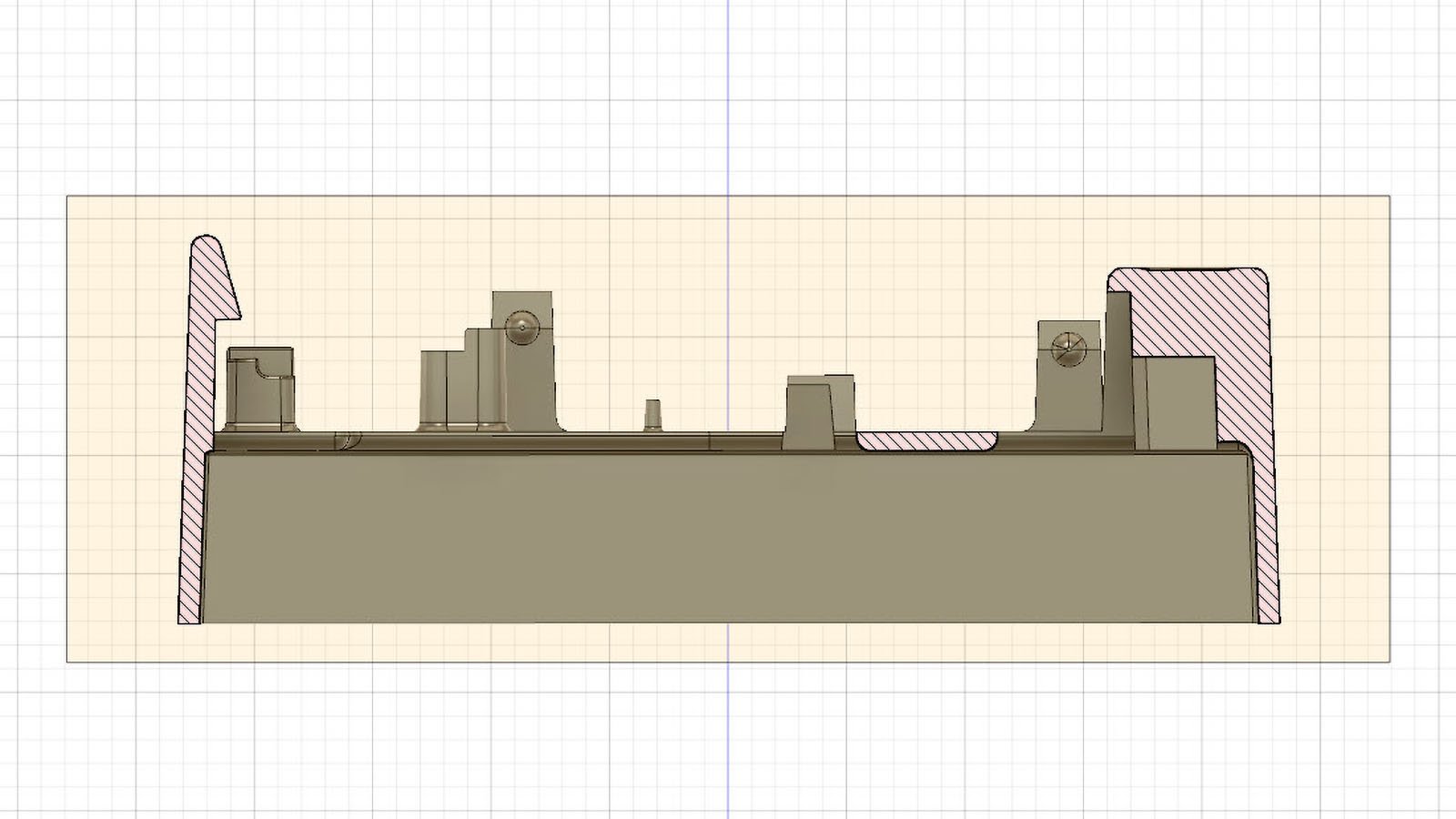

Having uniform wall thickness is important for the injection molding process. Here we will discuss why that is and how to design for molding.

If you’ve been inside a mold shop you’ve likely seen a few electrical discharge machines (EDM). Here’s how they work and how he technology is utilized.

Exceeding a million mold cycles goes much further than material choices or a hardness level. Designing for longevity and serviceability is critical.

There are a handful of different materials used for building injection molds. It’s important to understand the application of each.

© 2026 Basilius. All Rights Reserved.