Turning is a generic term used in the CNC industry to represent the use of a lathe. A lathe’s main function is to create round parts; however, as you will see, a lathe can have much more functionality. The lathe has a chuck that holds and spins the workpiece. The tooling is then moved around the workpiece to remove material. A simple lathe will have tooling that can move in two axes. In more advanced CNC turning equipment, more axes (directions of movement) are utilized to expand the functionality of the lathe. The added axes could be multiple chucks for different stages or the addition of milling type components to create more advanced features.

CNC Lathes

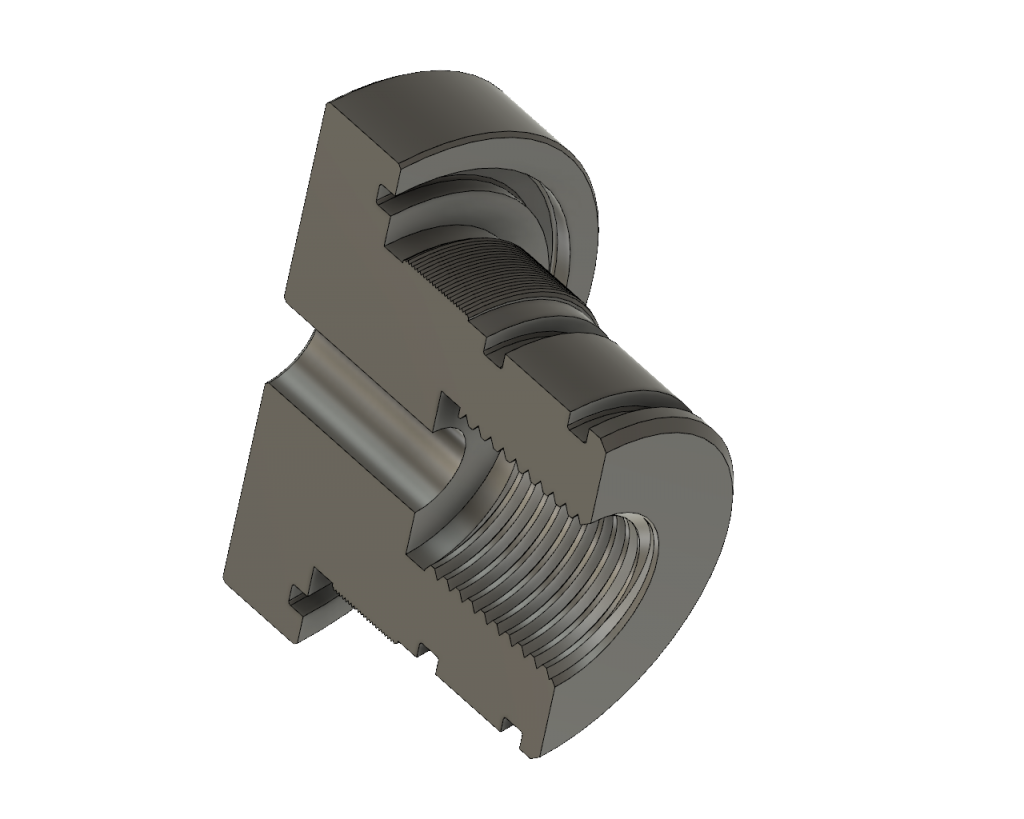

Like CNC milling, CNC lathes can use various types of tooling to create different features in round parts. These could be features like o-ring grooves, internal and external threads, face grooves, and so on. Lathes will also have a tailstock located opposite and in line with the chuck. The tailstock is used for holding a long workpiece or for completing various drilling functions. Figure 1.1 is a sectioned (cut in half) part that would be produced using a CNC lathe. Features include internal threads, external threads, outer diameter groove, inner diameter groove, and a face groove.

Live Tooling Lathes

Live tooling lathes are a combination of a mill and a lathe. Like a lathe, there is a chuck holding and spinning the workpiece; however, the tooling is much more advanced. There are various tooling heads mounted to a turret. The turret allows for anything from standard lathe type tooling to mill type tooling. The added functionality makes it possible to dill and mill features off-center or perpendicular to the chuck rotation. Check out our video of a live tooling lathe running at Basilius.

Advanced Lathe Operations

Like many other CNC operations, the level of machine capability in the CNC turning space keeps increasing to meet the demands of different industries. Our friends at Mazak have several different lathes that are meeting and exceeding these needs. In the videos below, you can see some much more advanced CNC turning/milling operations.

Check out this page for more information on designing for CNC Machining.