When you are in the beginning stages of the injection molding process, the first choice you will make is choosing a plastic mold manufacturing partner. With thousands of mold builders around the world, it’s easy to wonder if it matters who builds your mold. However, choosing a mold builder is one of the most critical parts of your injection molding process.

The partner you select not only should deliver on the mold design requirements but also, should prototype the part, aid in design adjustments, and much more. Learn our tips for sourcing the best mold builder for your application and learn why choosing a partner with in-house tooling capabilities is advantageous for long-term success.

The Biggest Molding Misconception

It’s common that, when we first talk to a new prospect or customer, they tell us the following:

“We are only concerned about getting a quality plastic part and keeping the tool cost as low as possible.”

While mold development costs may feel steep upfront, it is important to think about part savings over the long haul when developing a mold. Sourcing decisions are critical; your company and your reputation are at stake. Consider the following when sourcing your mold:

1. Mold Cost

The cost of a mold makes up a relatively small portion of the overall program cost. It is possible that the small savings a molder achieves by outsourcing to a low-cost tool builder does not provide any real long-term savings. It may, in fact, actually cost more. Although this statement is generally true, a molds percentage of the overall program cost will vary based on part complexity, annual volume, and program life.

2. Repairs and Revisions

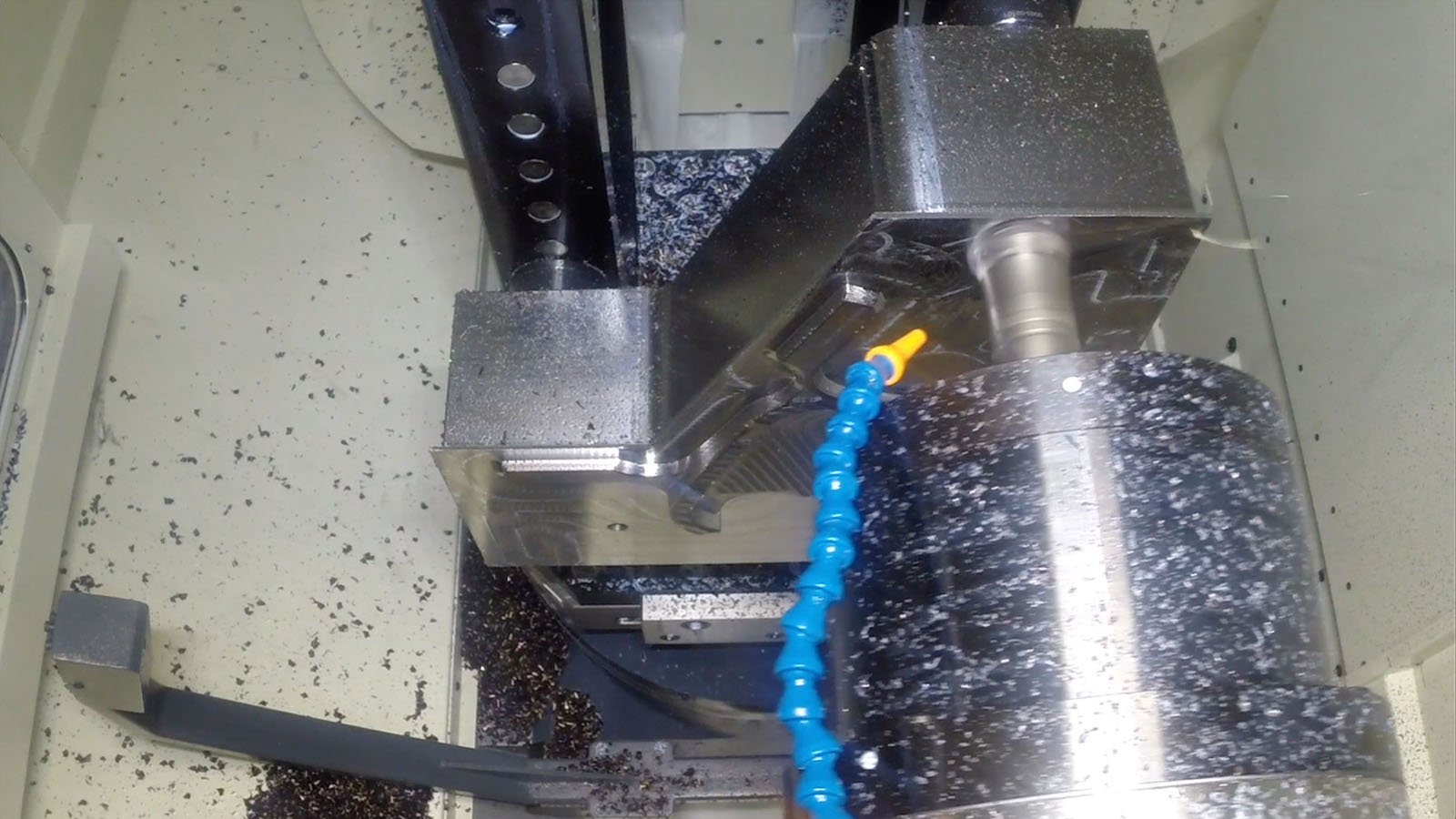

Even under the best of circumstances, molds need to be revised, repaired, and maintained. A molder with in-house tool building capabilities has the ability and motivation to quickly take care of tooling problems because they are working directly for you. Molders with in-house tool capabilities are not dependent upon the work schedule of a sub-supplier. Therefore, their production is not bogged down by that sub-supplier’s lack of urgency in completing the job or transportation delays.

3. Quality Tools

Tools with design or quality issues may require additional and potentially significant costs to fix downstream. “Band-aid” style repairs are generally unreliable and make process stability (part quality) difficult to achieve. And finally, as the owner of the mold, tool issues will complicate a mold transfer should it become necessary for you to find a new molder.

A molder with in-house tool building capabilities is keenly aware of how a tool needs to be built for performance and durability. Because the molder is the one that must deal with issues caused by poor tooling, they are highly motivated to build great tools. We believe that “Being a molder makes us a better tool builder, and being a tool builder makes us a better molder”.