What Is Gun Drilling?

Gun drilling, also known as deep hole drilling, is the process of using a long cutting bit to create a specific diameter hole in a part at extreme depths. Allowing you to drill holes not typically possible with standard methods and equipment. The gun drilling process has been around for decades. Originally developed for drilling gun barrels, the process is now being used in many other applications. Our “What is Gun Drilling and When to Use It” article covers the basics of gun drilling, but today, we’re going to dive deeper into the subject.

Let us help with every aspect of your drilling project. Request a quote today to get started.

LENGTH TO DIAMETER RATIO

Limiting Factors

The biggest factors that limit the depth of any drilling operation is cooling and chip removal. In the case of the standard spiral drill, it becomes more difficult to get cooling to the cutting area and remove chips the deeper the drill goes. When higher length to diameter ratios are needed, different technologies like gun drilling machines are deployed to combat these factors.

Using through spindle coolant and specialty drills it’s possible to achieve length to diameter ratios of 30:1 or more. Through the spindle coolant is typically an additional option of CNC equipment where coolant is running through the spindle and into specialty tooling to get coolant to cutting face of the tool. This helps keep the hole and drill cool but also to quickly remove chips from inside the hole.

You can see in the video below, how big of a difference through the spindle coolant can make when compared to traditional drilling.

This is a great system but imagine you needed a .500 hole to be 48 inches deep (l:d of 96:1). This is where gun drilling comes in.

The Benefits of Gun Drilling Machines

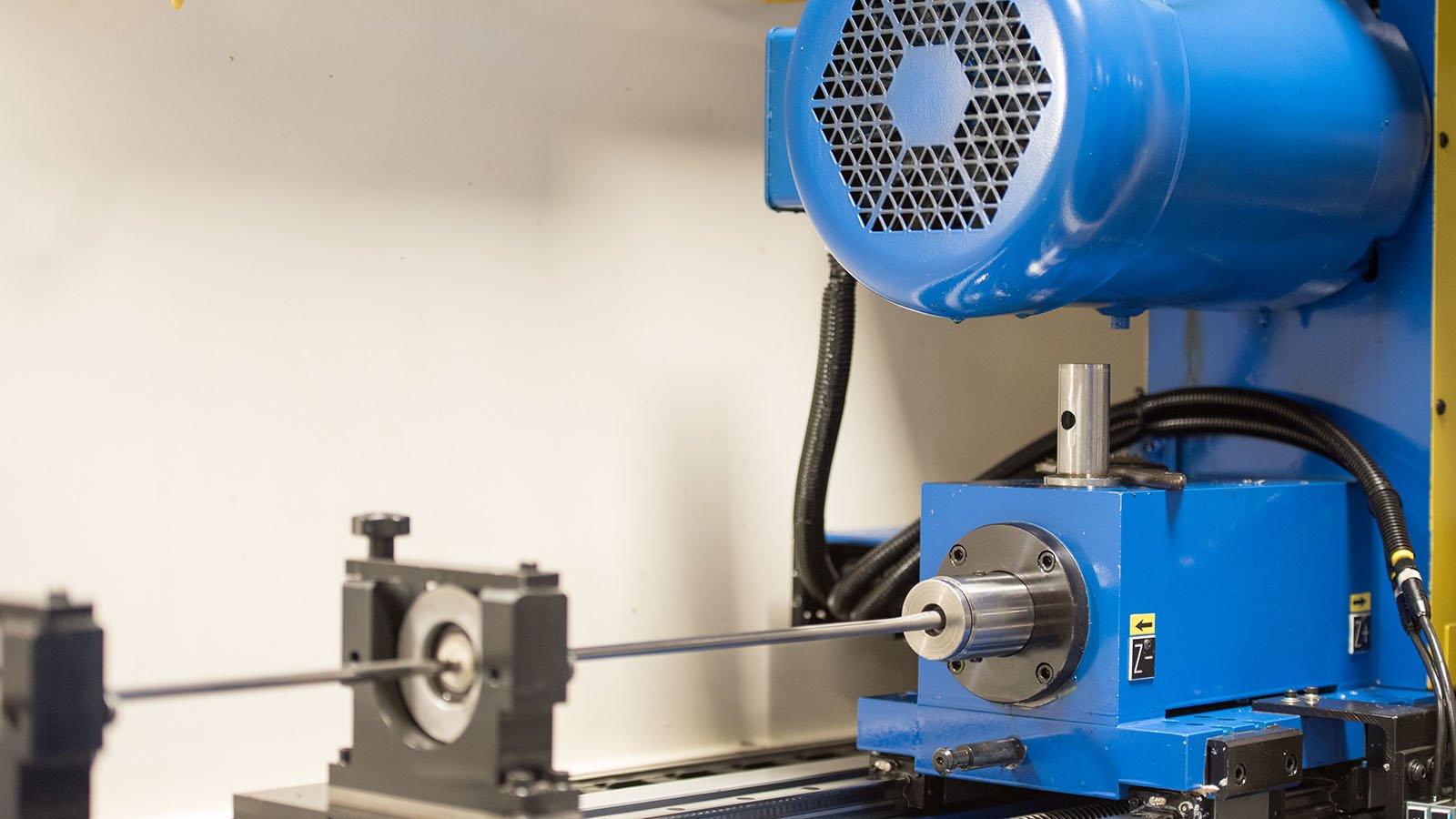

Another unique aspect of gun drilling is the way the drill is supported. In standard drilling operations, the drill is fixed to the spindle at one point on the drill. Therefore, the depth limit is also set by the length of the drill and possibly by limits of axis movement on the machine. In gun drilling, the drill is supported at the beginning of the hole. During drilling the drill moves through bearings to stays supported as the drill advances.

Using the gun drilling process, it’s possible to get l:d ratios up to 400:1 using specialty gun drilling equipment. More common for standard gun drilling equipment is hole sizes from .125 to 2.00 inches with l:d ratios off 200:1 or less.

Gun Drilling with Basilius

At Basilius, we’ve had a gun drill in our shop for a few decades. For internal processes, it has proven to be a reliable source for drilling cooling lines in large tooling blocks. At the same time, we have consistently been a source to our customers in different industries. Our typical range is .250 – 1.00 in diameter and up to 48 inches in depth.

Not only are we experts in gun drilling but we provide a full spectrum of CNC Machining services including; turning, milling, RAM EDM, Wire EDM, and grinding. Our knowledgeable team is prepared for even the most complex CNC projects. With a wide range of CNC capabilities, precision tooling, and decades of experience, you can depend on Basilius to handle your CNC project, no matter the difficulty.

Contact us or request a quote to get started on your CNC Machining project.