The challenge of drilling holes (especially deep holes) is the removal of the material that is being cut away. A traditional twist drill contains flutes to allow the removed material to escape. The material being cut away is used to push out the material that has already been cut. This is a low-cost way to drill holes but is not efficient when drilling holes at deeper depths.

Let us help with every aspect of your drilling project. Request a quote today to get started.

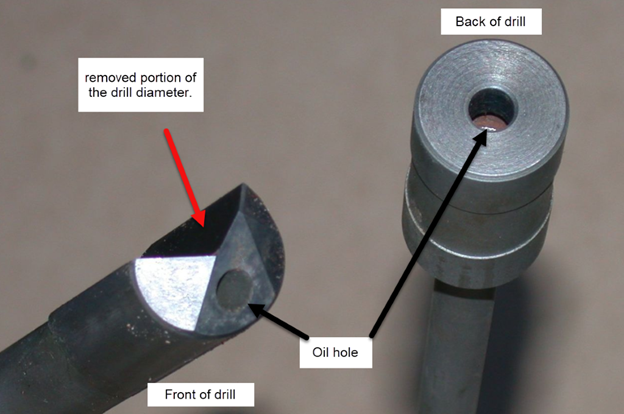

A more efficient way to drill holes to deeper depths is referred to as Gun Drilling. A gun drill contains a hole within the drill diameter, that is used to force oil into the area being cut. High-pressure oil is pumped through this hole to force the material being cut to escape. A portion of the diameter is removed, to allow this material to escape.

All injection molds contain multiple cooling channels (holes) to maintain the temperature of the tool steel. These holes are typically 3/8” to 7/16” in diameter and have a combined length of over 50”.

Gun dRILLING with Basilius

To maintain the efficiency of our mold building process, Basilius has invested in a dedicated gun drilling machine. Our range for drilling holes is .250” to 1.000” in diameter, with a depth limitation of approximately 40”. Dedicated gun drilling machines are expensive and not a common machine found in a typical machine shop. Many local manufacturing companies have utilized Basilius’ Gun Drilling services, as they see this as a low-cost method of drilling deep holes.

Contact us or request a quote to get started on your gun drilling project.