pRECISION eQUIPMENT

Quality Tools Built to Last

We take great pride in our equipment. Because your tool builder’s equipment matters. From injection molding equipment to CNC machines, and EDM to a variety of support machines, we have the technology to ensure part consistency down to extreme tolerances.

Our selection of in-house equipment consists of; Molding Machines, RAM EDM, Wire EDM, Milling, Graphite Milling, 3D Printers, Grinding, Lathes, and more. No matter what your need, we have the machine to complete your project. Discover more about our equipment and various machines below. Looking for other equipment not listed? Contact us today and we can discuss your needs.

Quicklinks

search our in-house equipment

Looking for a specific piece of equipment? Use our quicklinks buttons below to search our in-house equipment list. Want to see everything? Continue scrolling and explore our expansive list of equipment.

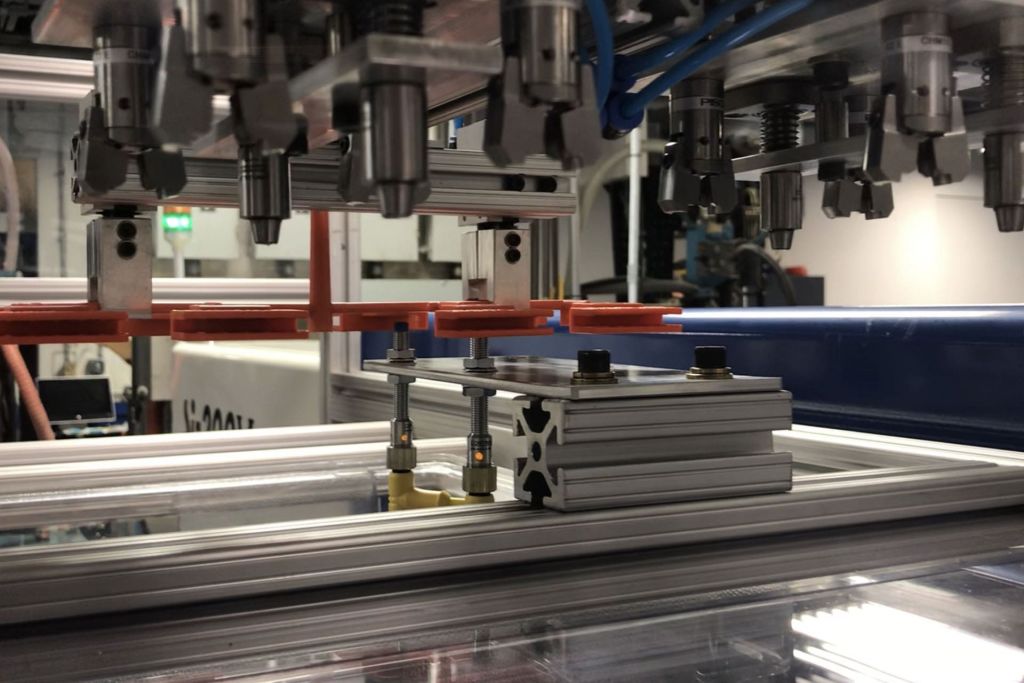

Molding Machines

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 2.31 oz. (28mm) |

| Tie Rod Spacing | 14.17” x 12.79” |

| Mold Thickness (Min / Max) | 5.91” / 14.96” |

| Daylight (Max.) | 25.63″ |

| Clamp Travel (Max.) | 10.62″ |

| Ejector Stroke | 2.75″ |

| Platen Size | 19.68” x 19.68” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | YC-100S-11-8 |

| Year Purchased | 2021 |

| Machine Number | #6 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 2.936 oz. (32mm) |

| Tie Rod Spacing | 14.17” x 12.79” |

| Mold Thickness (Min / Max) | 5.91” / 14.96” |

| Daylight (Max.) | 25.63″ |

| Clamp Travel (Max.) | 10.67″ |

| Ejector Stroke | 2.84″ |

| Platen Size | 19.68” x 18.11” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | Yes |

| Robotics | Yushin Hop Five 550X |

| Year Purchased | 2011 |

| Machine Number | #11 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 1.43 oz. (24mm) |

| Tie Rod Spacing | 14.17” x 12.79” |

| Mold Thickness (Min / Max) | 5.91” / 14.96” |

| Daylight (Max.) | 25.63″ |

| Clamp Travel (Max.) | 10.67″ |

| Ejector Stroke | 2.84″ |

| Platen Size | 19.68” x 18.11” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | Yes |

| Robotics | YC-100S-11-8 |

| Year Purchased | 2012 |

| Machine Number | #12 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 2.38 oz. (28mm) |

| Tie Rod Spacing | 14.17” x 12.79” |

| Mold Thickness (Min / Max) | 5.91” / 14.96” |

| Daylight (Max.) | 25.63″ |

| Clamp Travel (Max.) | 10.67″ |

| Ejector Stroke | 2.84″ |

| Platen Size | 19.68” x 18.11” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | Yes |

| Robotics | Yushin Hop Five |

| Year Purchased | 2024 |

| Machine Number | #7 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 2.38 oz. (28mm) |

| Tie Rod Spacing | 14.17” x 12.79” |

| Mold Thickness (Min / Max) | 5.91” / 14.96” |

| Daylight (Max.) | 25.63″ |

| Clamp Travel (Max.) | 10.67″ |

| Ejector Stroke | 2.84″ |

| Platen Size | 19.68” x 18.11” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | Yes |

| Robotics | Yushin Hop Five |

| Year Purchased | 2025 |

| Machine Number | #15 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Vertical |

| Barrel Size | 3.0 oz. (24mm) |

| Tie Rod Spacing | |

| Mold Thickness (Min. / Max.) | 5.91” / 13.78” |

| Daylight (Max.) | 24.80″ |

| Clamp Travel (Max.) | 11.02″ |

| Ejector Stroke | 4.02″ |

| Platen Size | |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | No |

| Robotics | No |

| Year Purchased | 2007 |

| Machine Number | #8 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 6.747 oz. (40mm) |

| Tie Rod Spacing | 18.11” x 16.14” |

| Mold Thickness (Min. / Max.) | 5.91” / 20.08” |

| Daylight (Max.) | 34.30″ |

| Clamp Travel (Max.) | 14.22″ |

| Ejector Stroke | 4.02″ |

| Platen Size | 24.80” x 22.83” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | No |

| Robotics | Yushin YA-150 |

| Year Purchased | 2010 |

| Machine Number | #10 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 6.747 oz. (40mm) |

| Tie Rod Spacing | 18.11” x 16.14” |

| Mold Thickness (Min. / Max.) | 5.91” / 20.08” |

| Daylight (Max.) | 34.30″ |

| Clamp Travel (Max.) | 14.22″ |

| Ejector Stroke | 4.02″ |

| Platen Size | 24.80” x 22.83” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | No |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | Yushin Hop Five |

| Year Purchased | 2024 |

| Machine Number | #5 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 8.707 oz. (46mm) |

| Tie Rod Spacing | 20.07” x 18.11” |

| Mold Thickness (Min. / Max.) | 5.91″ / 21.66” |

| Daylight (Max.) | 37.45″ |

| Clamp Travel (Max.) | 15.79″ |

| Ejector Stroke | 4.02″ |

| Platen Size | 27.16” x 25.19” |

| Knockout Pattern | +/- 3.5″ |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | No |

| Robotics | Yushin YA-150 |

| Year Purchased | 2010 |

| Machine Number | #3 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 17.263 oz. (55mm) |

| Tie Rod Spacing | 22.00” x 22.00” |

| Mold Thickness (Min. / Max.) | 7.88” / 23.63” |

| Daylight (Max.) | 42.18″ |

| Clamp Travel (Max.) | 18.55″ |

| Ejector Stroke | 4.80″ |

| Platen Size | 30.71” x 30.71” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | Yushin YA-II 250 |

| Year Purchased | 2011 |

| Machine Number | #9 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 17.263 oz. (55mm) |

| Tie Rod Spacing | 24.00” x 24.00” |

| Mold Thickness (Min. / Max.) | 7.88” / 23.63” |

| Daylight (Max.) | 42.18″ |

| Clamp Travel (Max.) | 18.55″ |

| Ejector Stroke | 4.80″ |

| Platen Size | 30.71” x 30.71” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | Yushin YA-II 250 |

| Year Purchased | 2008 |

| Machine Number | #1 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 17.359 oz. (55mm) |

| Tie Rod Spacing | 24.00” x 24.00” |

| Mold Thickness (Min. / Max.) | 9.85” / 26.78” |

| Daylight (Max.) | 48.48″ |

| Clamp Travel (Max.) | 21.70″ |

| Ejector Stroke | 5.99″ |

| Platen Size | 32.28” x 32.28” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | No |

| Robotics | Yushin YA11-150 |

| Year Purchased | 2009 |

| Machine Number | #4 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 10.25 oz. (46mm) |

| Tie Rod Spacing | 24.00” x 24.00” |

| Mold Thickness (Min. / Max.) | 9.85” / 26.78” |

| Daylight (Max.) | 48.48″ |

| Clamp Travel (Max.) | 21.70″ |

| Ejector Stroke | 5.99″ |

| Platen Size | 32.28” x 32.28” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | N/A |

| Year Purchased | 2022 |

| Machine Number | #14 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 10.25 oz. (46mm) |

| Tie Rod Spacing | 24.00” x 24.00” |

| Mold Thickness (Min. / Max.) | 9.85” / 26.78” |

| Daylight (Max.) | 48.48″ |

| Clamp Travel (Max.) | 21.70″ |

| Ejector Stroke | 5.99″ |

| Platen Size | 32.28” x 32.28” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | N/A |

| Year Purchased | 2025 |

| Machine Number | #16 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 36.646 oz. (68mm) |

| Tie Rod Spacing | 31.80” x 31.80” |

| Mold Thickness (Min / Max) | 11.81” / 30.32” |

| Daylight (Max.) | 57.92″ |

| Clamp Travel (Max.) | 27.60″ |

| Ejector Stroke | 5.99″ |

| Platen Size | 42.00” x 42.00” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | No |

| Core Pull Control | No |

| Air Blast Control | No |

| Robotics | Yushin YA11-250S |

| Year Purchased | 2009 |

| Machine Number | #2 |

| Manufacturer | Toyo |

| Electric / Hydraulic | Electric |

| Horizontal / Vertical | Horizontal |

| Barrel Size | 36.957 oz. (68mm) |

| Tie Rod Spacing | 31.80” x 31.80” |

| Mold Thickness (Min / Max) | 11.81” / 30.32” |

| Daylight (Max.) | 57.92″ |

| Clamp Travel (Max.) | 27.60″ |

| Ejector Stroke | 5.99″ |

| Platen Size | 42.00” x 42.00” |

| Knockout Pattern | +/- 3.5″ & +/- (8” x 2”) |

| Valve Gate Control | Yes |

| Core Pull Control | Yes |

| Air Blast Control | Yes |

| Robotics | N/A |

| Year Purchased | 2010 |

| Machine Number | #13 |

ram edm

| Number Axis | 4 | ||

| Table Size | 31.00” x 22.00” | ||

| Table Travel | X: 25.60” | Y: 17.70” | Z: 13.80” |

| Tank Size | 42” x 29” | ||

| Tool Changer | 16 Station | ||

| Serial Number | E2501 | ||

| Year Purchased | 2001 | ||

| Number Axis | 4 | ||

| Table Size | 31.00” x 22.00” | ||

| Table Travel | X: 25.60” | Y: 17.70” | Z: 13.80” |

| Tank Size | 42″ x 29″ | ||

| Tool Changer | 8 Station | ||

| Serial Number | C94-61N | ||

| Year Purchased | 1995 | ||

| Number Axis | 4 | ||

| Table Size | 31.00” x 22.00” | ||

| Table Travel | X: 25.60” | Y: 17.70” | Z: 13.80” |

| Tank Size | 42” x 29” | ||

| Tool Changer | 16 Station | ||

| Serial Number | B94-53N | ||

| Year Purchased | 1996 | ||

| Number Axis | 4 | ||

| Table Size | 31.5” x 21.7” | ||

| Table Travel | X: 25.60” | Y: 17.70” | Z: 13.80” |

| Tank Size | 43.3” x 29.5” | ||

| Tool Changer | 16 Station | ||

| Serial Number | E021437 | ||

| Year Purchased | 2023 | ||

3D Printers

| Build Envelope X | 120 mm |

| Build Envelope Y | 68 mm |

| Build Envelope Z | 155 mm |

Milling

| Pallet | 19.7″ x 19.7″ |

| X | 28.7″ |

| Y | 25.6″ |

| Z | 31.5″ |

| Spindle RPM | 14,000 RPM |

| Rapid Traverse | 2,362 IPM |

| Cutting Feedrate | 1,968 IPM |

| Maximum Workpiece | ø31.5″ x 39.4″ |

| Maximum Payload | 1,540 lbs |

| ATC Capacity | 134 |

| Tool to Tool | 0.9 Sec |

| Chip to Chip | 2.5 Sec |

| Maximum Tool Length | 20.1″ |

| Maximum Tool Diameter | 6.7″ |

| Maximum Tool Weight | 26.4 Lbs |

| Year Purchased | 2018 |

| Table Size | 39.40” x 19.70” | ||

| Table Travel | X: 35.40” | Y: 19.70” | Z: 17.70″ |

| Spindle RPM | 20,000 | ||

| Table Weight | 1432 | ||

| Serial Number | V150122 | ||

| Year Purchased | 2011 | ||

| Table Size | 39.40” X 19.70” | ||

| Table Travel | X: 35.40” | Y: 19.70” | Z: 17.70″ |

| Spindle RPM | 14,000 | ||

| Table Weight | 1,543 | ||

| Serial Number | 809 | ||

| Year Purchased | 2000 | ||

| Table Size | 55.10” x 27.60” | ||

| Table Travel | X: 47.20” | Y: 27.60” | Z: 25.60″ |

| Spindle RPM | 20,000 | ||

| Table Weight | 5,500 | ||

| Serial Number | 420 | ||

| Year Purchased | 2003 | ||

| Diameter Capacity | 27.4” |

| Length Capacity | 21” |

| Chuck Size | 10 in. |

| Table Size | 27.50” x 16.50” | ||

| Table Travel | X: 22.00” | Y: 16.10” | Z: 17.70” |

| Spindle RPM | 10,000 | ||

| Table Weight | 660 | ||

| Serial Number | 45 | ||

| Year Purchased | 2007 | ||

| Table Size | 66.90” x 33.80” | ||

| Table Travel | X: 59.00” | Y: 33.80” | Z: 29.50” |

| Spindle RPM | 6,000 | ||

| Table Weight | 4,400 | ||

| Serial Number | 475 | ||

| Year Purchased | 2010 | ||

| Table Size | 50.00” x 10.00″ | ||

| Table Travel | X: 32.00” | Y: 16.00” | Z: 16.00″ |

| Spindle RPM | 4,200 | ||

| Table Weight | 850 | ||

| Serial Number | 183DY629 | ||

| Year Purchased | 2018 | ||

| Table Size | 50.00″ x 10.00″ | ||

| Table Travel | X: 32.00” | Y: 16.00” | Z: 16.00″ |

| Spindle RPM | 4,200 | ||

| Table Weight | 850 | ||

| Serial Number | 083CK16578 | ||

| Year Purchased | 2008 | ||

| Model | 3A-1.000-7.5-48-48×32 | ||

| Table Travel | X: 24” | Y: 16” | Z: 48″ |

| Drill Capacity | .25″ to 1.0″ | ||

| Work Table | 32 X 48 | ||

| Weight Limit | 3000 Lbs | ||

Graphite Milling

| Table Size | 29.53” x 15.75” | ||

| Table Travel | X: 23.62” | Y: 15.75” | Z: 15.75″ |

| Spindle RPM | 20,000 | ||

| Table Weight | 550 | ||

| Serial Number | 558 | ||

| Year Purchased | 2001 | ||

| Table Size | 39.40” x 19.70” | ||

| Table Travel | X: 35.4” | Y: 19.70” | Z: 17.7″ |

| Spindle RPM | 20,000 | ||

| Table Weight | 1432 | ||

| Serial Number | V150527 | ||

| Year Purchased | 2013 | ||

wire edm

| Table Size | 28.5” x 23.00” | ||

| Table Travel | X: 17.7″ | Y: 11.8” | Z: 12.6” |

| Table Weight | 1764 lbs | ||

| Serial Number | W7104 | ||

| Year Purchased | 2006 | ||

| Table Size | 28.5” x 23.00” | ||

| Table Travel | X: 17.7″ | Y: 11.8” | Z: 12.6” |

| Table Weight | 1764 lbs | ||

| Serial Number | W7510 | ||

| Year Purchased | 2008 | ||

| Capacity | 46″ | 26″ | 16.5″ |

| Table Travel | 21.5″ | 15.5″ | |

| Z Travel (Burn Vector) | 8″ | ||

| Max Weight | 1000 lbs |

Grinding

| Table Travel | 40” x 20” | ||

| Serial Number | 78051 | ||

| Year Purchased | 2007 | ||

| Table Travel | 32” x 16” | ||

| Serial Number | 76037 | ||

| Year Purchased | 1999 | ||

| Table Travel | 18” x 6” | ||

| Serial Number | 48034 | ||

| Year Purchased | 1999 | ||

| Table Travel | 18” x 6” | ||

| Serial Number | 48248 | ||

| Year Purchased | 2004 | ||

| Table Travel | 18” x 6” | ||

| Serial Number | 48248 | ||

| Year Purchased | 2004 | ||

| Serial Number | 13166 | ||

| Year Purchased | 2013 (refurbished) | ||

| Capacity (dia.) | 9.5 | ||

| Serial Number | 1178-449 | ||

| Year Purchased | 2013 (refurbished) | ||

| Capacity (dia.) | 11 | ||

| Serial Number | 2991 | ||

| Year Purchased | 1969 | ||

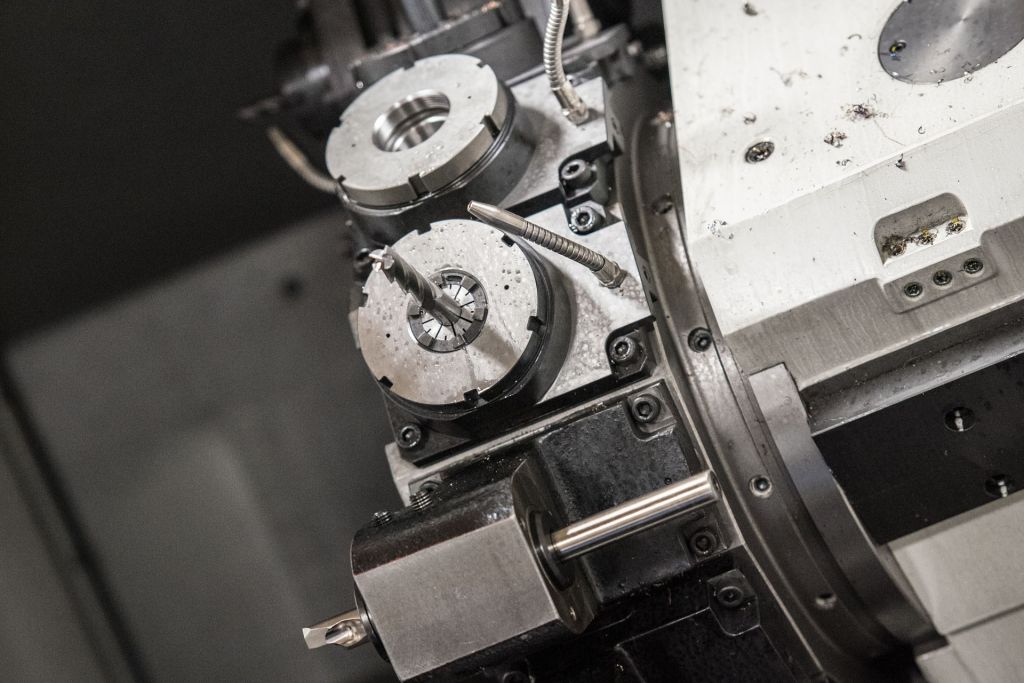

Lathes

| Diameter Capacity | 18.00” |

| Length Capacity | 40.00” |

| Serial Number | 062CQ14449 |

| Year | 2006 |

| Diam. Capacity | 16.875″ |

| Length Capacity | 39.33″ |

| Serial Number | 220228 |

| Year | 1991 |

Support Equipment

Toggle Content

| X Travel | 27.560 | ||

| Y Travel | 39.370 | ||

| Z Travel | 23.620 | ||

| Weight Capacity | 1760 | ||

eQUIPMENT in Action

Quality Tools = Equality Products

At Basilius, we take pride in the work that we do and the equipment that we utilize. Take a peek behind the scenes at Basilius and explore our in-house equipment in action by pressing play.

Featured Equipment Articles

Learn more from Our Expert Team

The Complete Guide to Warehouse Automation

Warehouse automation can be a complicated task. However, when done correctly the rewards are endless. Here we discuss warehouse automation in its entirety and how you can start adopting it in your business.

Improve Operations with a Robotic Palletizer Machine

A robotic palletizer machine can go a long way to help you improve operations and productivity. How? That’s exactly what we’re about to cover.

CNC Turning Equipment and Operations

CNC lathes can produce a large variety of parts, depending on the machines functionality. These are the different machines and how they operate.