Understanding the Cavitation Cost Benefit Analysis

Cavitation can have huge implications on both piece price and mold cost. See how we can do a cost benefit analysis to find the right fit.

At the end of the day, it all comes down to delivering quality injection molding …“right on time”. The molded part is the culmination of everything we do and best demonstrates the strength of our injection mold design, tooling, and management systems. When you choose Basilius Inc. for your injected molded parts you can expect quality, consistency and accountability from start to finish.

We pride ourselves on our versatile expertise and commitment to excellence, which allows us to serve a spectrum of industries. Our core competencies are in injection molding, industrial automation, and CNC machining, enabling us to deliver superior quality products with unparalleled precision and efficiency. By harnessing cutting-edge technology and leveraging our vast industry knowledge, we consistently exceed expectations and drive innovation across the industries we serve.

» Insert Molded Window Lifts

» Oil Filter Screens

» Window Brackets

» Window Location Pins

» Overmolded Screw Plungers

» UV Phototherapy Combs

» Vessel Preparation Components

» Power Washer Spray Handle Assemblies

» Well Caps and Fittings

» Fluid Transfer Fittings

» Goggle Grips®

» Handy Safety Knife®

» Accessory Rail for Ballistic Helmet

» Overmolded Pistol Grip

» Insert Molded Buttstock

We are injection molding experts. With a complete understanding of what it takes to produce a successful plastic injection molding part, we can help with all of your needs from prototype to production. Every part is different. Our manufacturing process was designed to focus on what makes your part unique allowing us to build you a high quality part that will stand up to the tests of time. Want to discuss your project with us? Fill out our simple online injection molding quote form and we’ll be in touch.

Price, quality, and on time delivery are words that Basilius Inc. live by. During the past 15 years it has been my pleasure to work with the Basilius Team on many programs and projects. Scott and his team deliver total project management from design, using the latest technology, through sampling and production. Basilius Inc. is my selection when quality of design, tool life, and on time delivery are the projects benchmark

When Brian Wholeman, CEO and Founder of EZ Shade reached out we instantly knew that we could help with the development of his product from start to finish. Brian had been searching for a one stop shop that could not only complete the injection molding process but could provide full service to make the production of his clip on light shades for bare or exposed ceiling and wall lights a breeze.

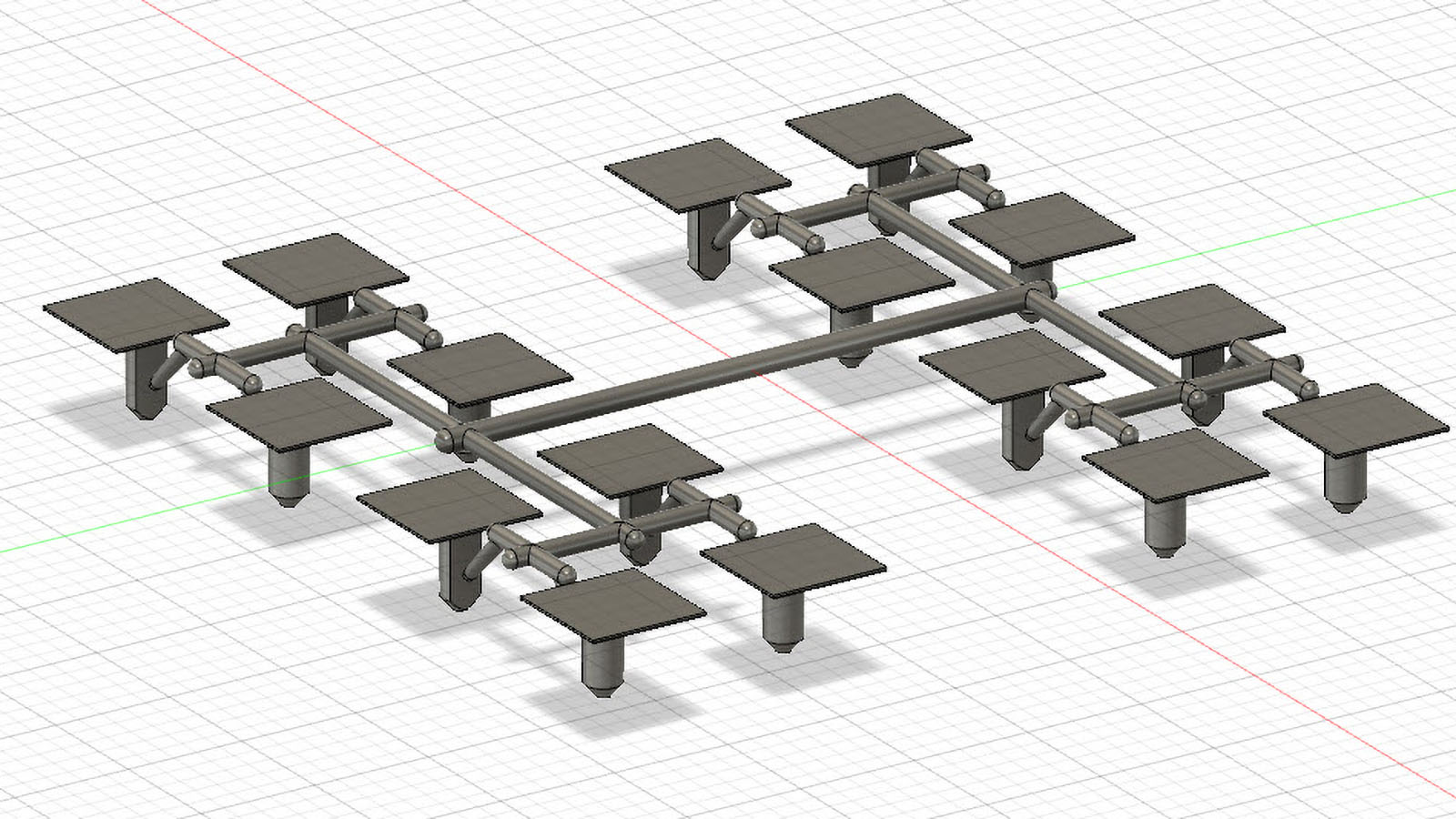

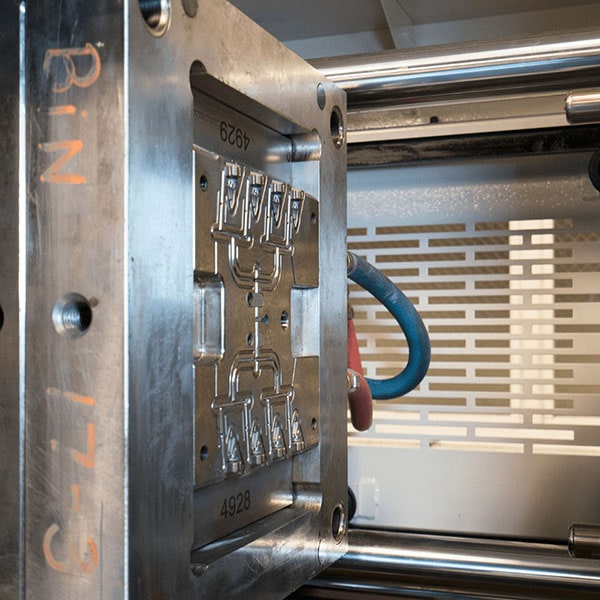

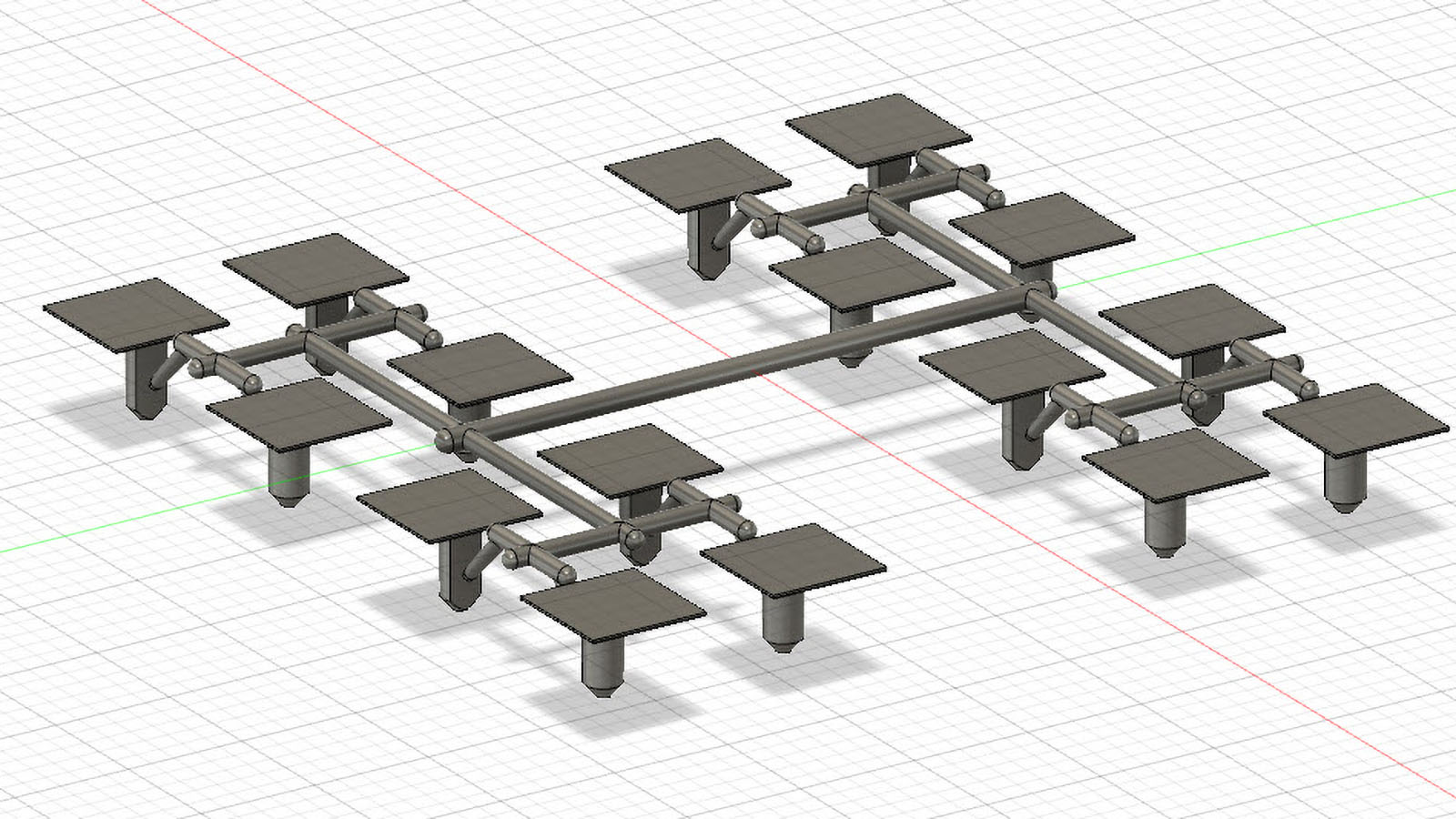

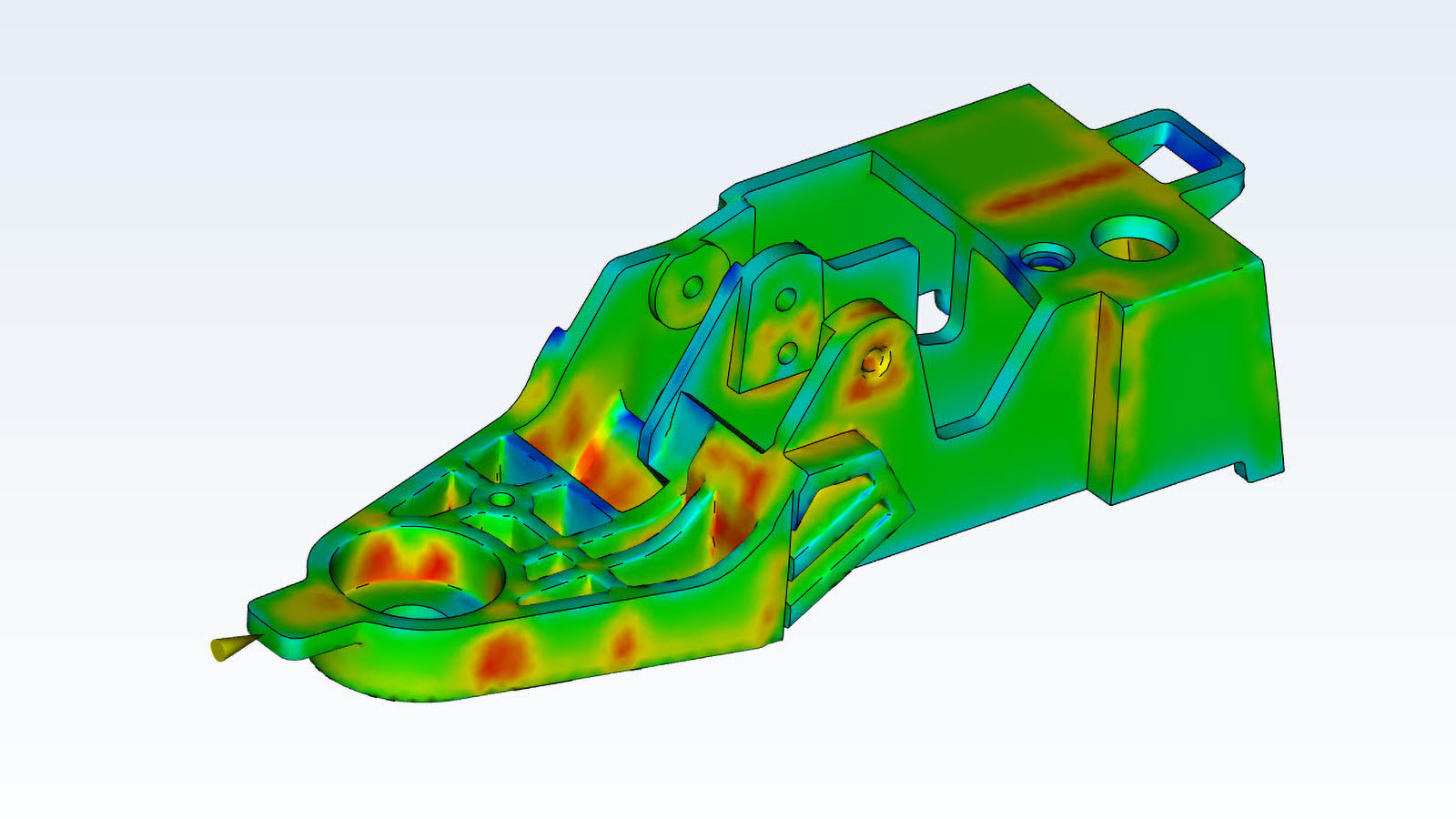

Cavitation can have huge implications on both piece price and mold cost. See how we can do a cost benefit analysis to find the right fit.

Having uniform wall thickness is important for the injection molding process. Here we will discuss why that is and how to design for molding.

The strength of being a mold builder and injection molder is realized through the entire process. From initial design to long term production.

© 2025 Basilius. All Rights Reserved.