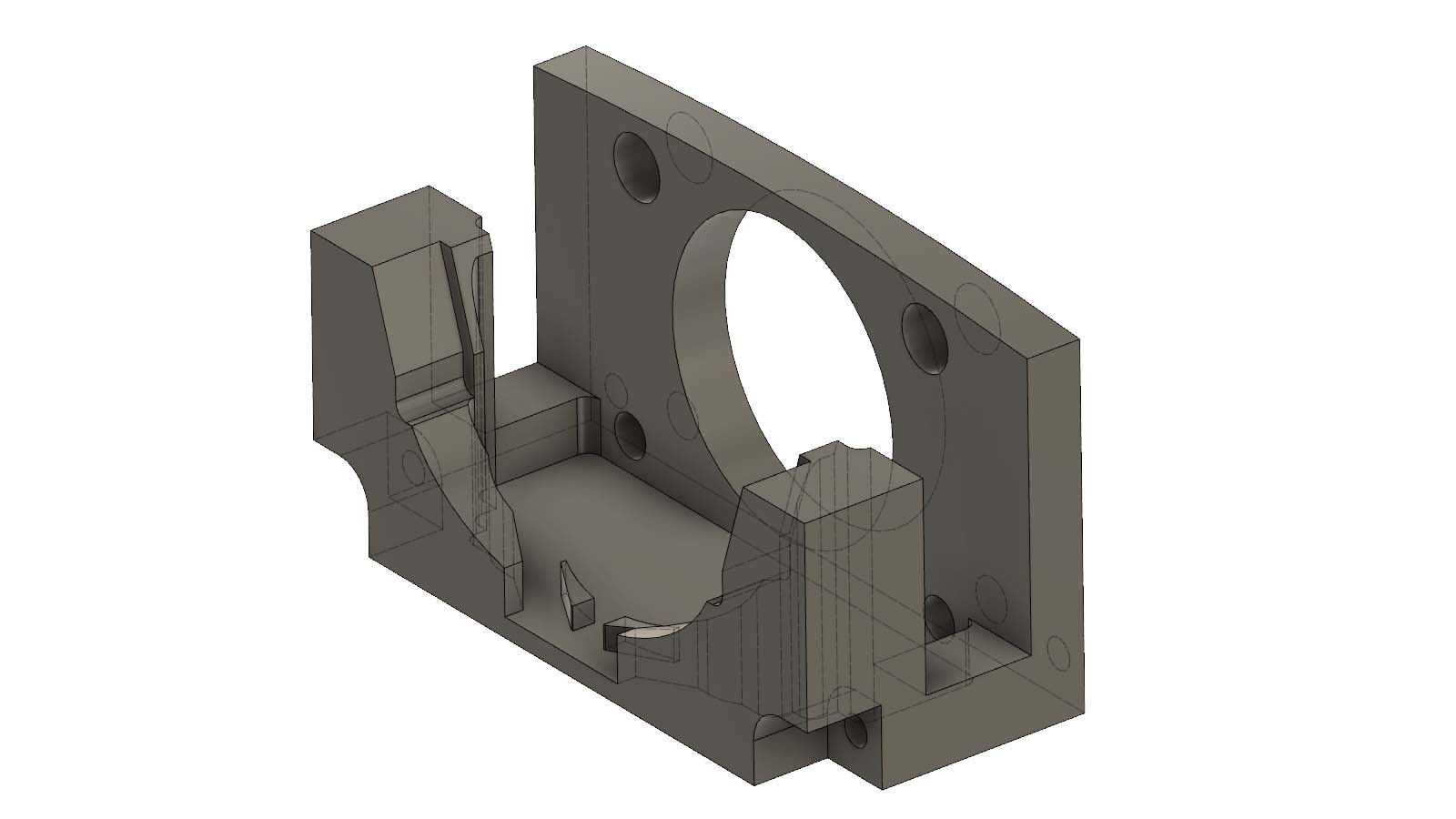

CNC components can serve a huge spectrum purposes. From a simple bearing housing to critical aircraft components the applications are endless. At Basilius, we’ve been providing CNC machining services for decades. In that time, we’ve found some common cost savings opportunities for our customers’ CNC components. Below you will find some common areas that reduce machine time, reduce setup time, and reduce costs.

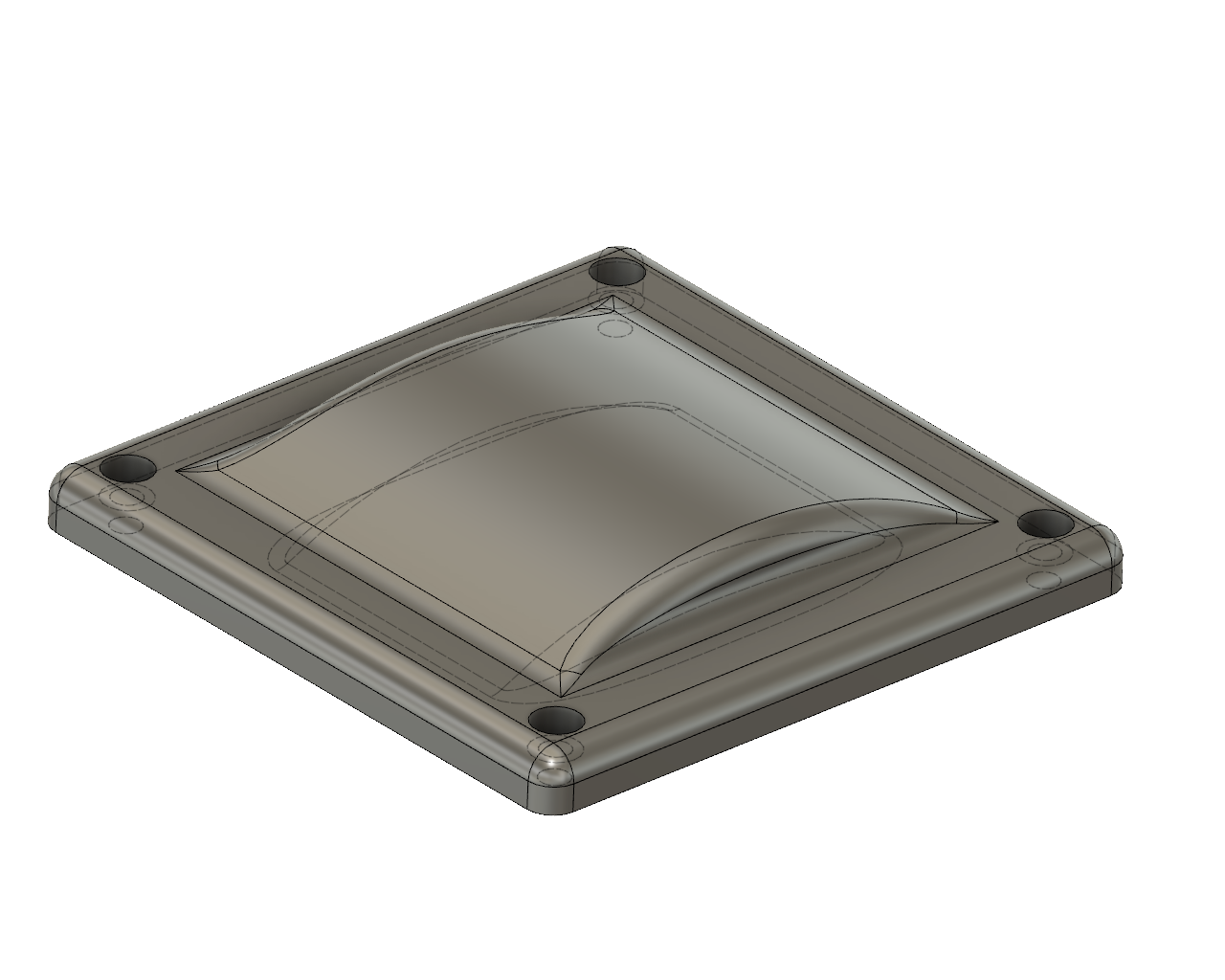

Contours

Contours are simple to create in CNC operations, but they require longer cycle times to produce. Unless a contour is needed for the part to function correctly, it is best to simplify the surfaces to save on machine time (part cost). The images below show the before (first image) and after of a part with and without a contour. Eliminating this contour could drastically reduce the cost of the component.

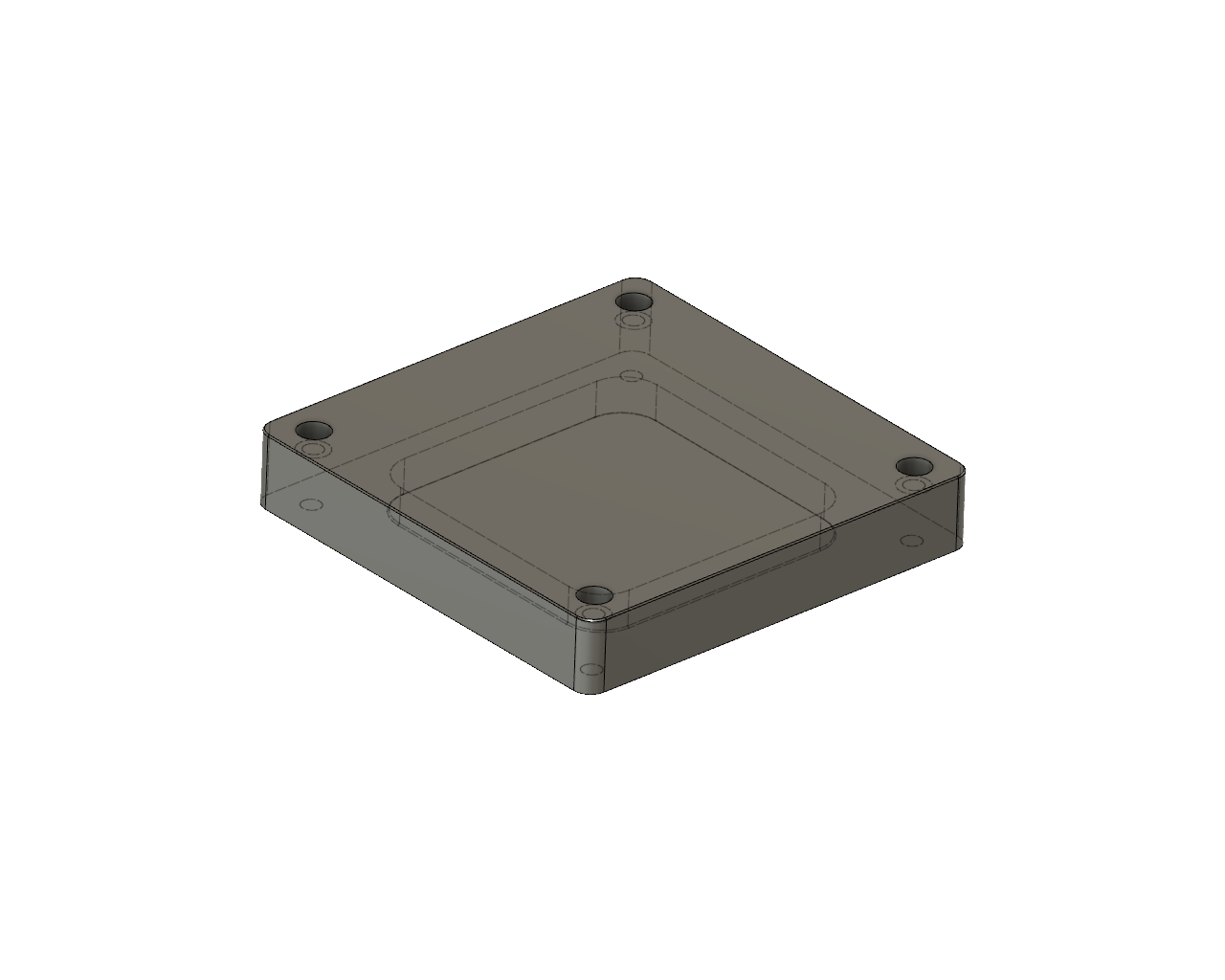

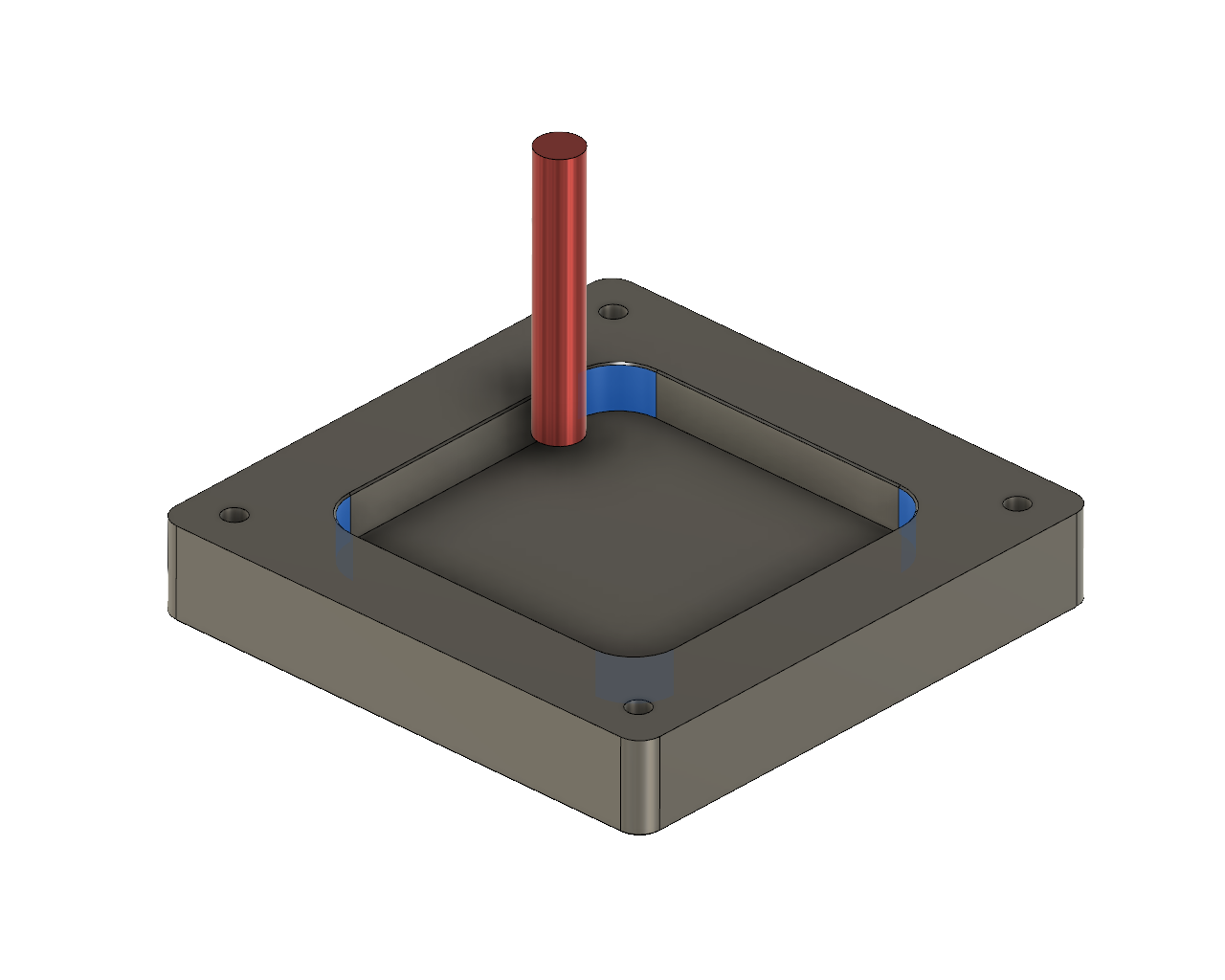

Fillets / Radii / Chamfers

Fillets and radii are good design features for increasing strength and resisting cracking. They also make parts easier to handle and more aesthetically pleasing. Depending on the CNC process, fillets and radii may be inevitable; but in other cases, they may cause unnecessary complications.

As an example, since milling operations use a rotating bit, inside corner radii are inevitable in a milling operation. The image below shows an example part with an inside corner radius. A simplified mill tool is shown in red for reference.

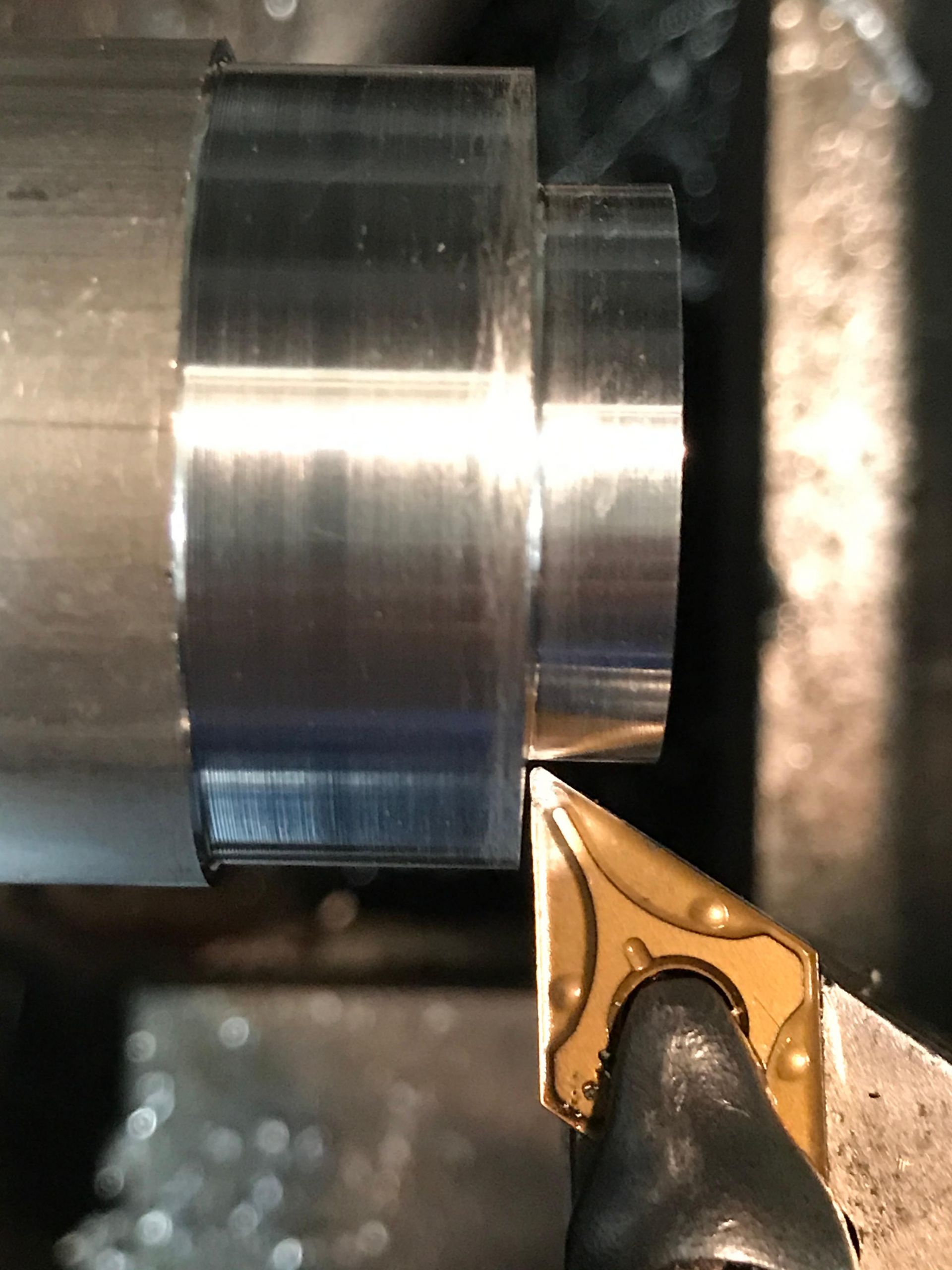

The Image below shows a common tooling insert for a lathe (gold color). Nearly all of these types of inserts have a rounded (radiused) end. The radius helps to cut away material more efficiently but will also generate a fillet on inside corners during CNC operations. If an inside corner for a turned component needs to be sharp, special “zero radius” tooling inserts will need to be used, which results in an added operation and tool setup. As a general rule, it is best to allow for fillets on turned parts in order to avoid the added operation.

Limiting Setups

Setups are required any time a component needs to be put into a fixture or clamped into a machine. Each setup adds to machine time in the worst way. That is, the machine is on but not cutting material. Thus, moving parts around opens up room for error and wastes machine time. This is why multi-axis machines and pallet changers are such a huge advantage. Multi-axis machines can access more sides of a part, which reduces setups. Pallet changers allow an operator to set up the next set of parts while another set is cutting.

Depth and Size

The length to diameter ratio (L:D ratio) discussed earlier also applies to CNC milling. Designing small features that are hard to reach is likely to increase the cost of a component. An example is a thin and deep pocket. For CNC milling, deep and narrow areas require specialized tooling and are time-consuming to produce. They may even require the use of EDM equipment, requiring more setup time and an additional process.

Materials

When designing a component for CNC machining, you want to consider strength requirements, chemical resistance, thermal stability, cost, and other such factors. Metals have diverse material properties which drive the performance characteristics of the final product. These various properties are great, but they should be balanced against raw material costs and machining cost. For example, if your part is specified to be stainless steel, you will find that there are several different grades of stainless steel that have large differences in both cost and material properties. Furthermore, some stainless steels are more cumbersome to cut than others, which means they will cost slightly more to CNC machine.

Tolerances

Tolerances are important for CNC machining operations to ensure consistent part quality and functionality. It’s also important to understand what areas or features of your component matter and which ones do not (relatively speaking).

Tolerancing areas to be less critical helps reduce the cost of the part. For example, if every dimension on a print is specified to be +/-.0001, machine operators will have to be careful to maintain that level of accuracy. These dimensions will all need to be confirmed to be accurate, set-up time could be longer, and the programming may need to be modified to run more slowly or make repeated movements.

When setting tolerances, it’s also important to consider how a dimension can be confirmed once the part is complete. For example, setting tight tolerances on complicated contours may require difficult checking procedures or require interpretation from other dimensions. That’s not to say that setting tight tolerances should not be a priority, it’s that setting tight tolerances on areas that don’t actually require it takes extra time and may increase the cost of the part unnecessarily.

Check out this page for more information on designing for CNC Machining.